Home » News

News

Home » News

2026-03-05

At market close in early March 2026, benchmark primary aluminum traded around USD 3,200–3,400 per metric ton, which equals roughly USD 1.45–1.55 per pound; regional delivery, grade, contract terms, taxes,...

2026-03-05

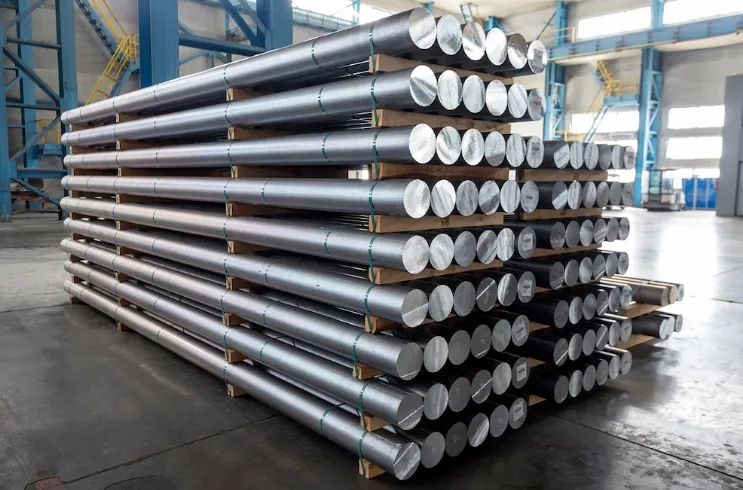

As of early March 2026 the global benchmark for primary aluminium sits around $1.45 to $1.55 per pound and delivered aluminium billet prices normally trade above that benchmark by a regionally variable...

2026-03-04

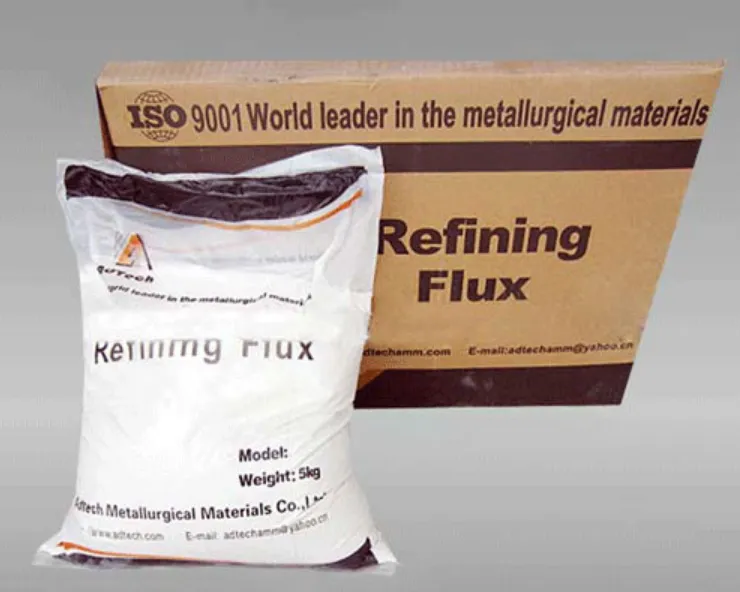

When correctly specified and applied, high-quality aluminium flux powder dramatically reduces metal loss to dross, eliminates surface oxides and entrained inclusions, lowers hydrogen-related porosity,...

2026-03-04

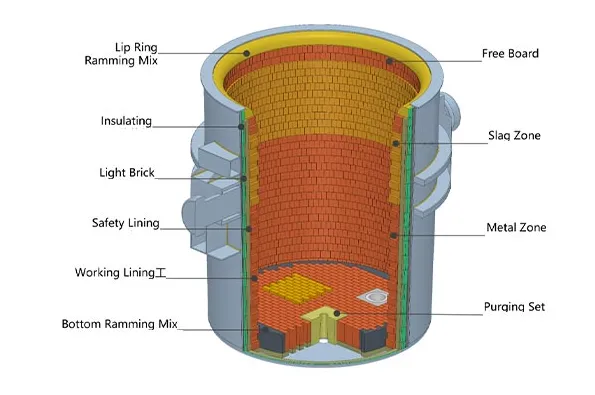

The single most effective way to raise aluminum furnace efficiency, lower downtime, and reduce total melting cost is to specify a multi-layer refractory lining system that pairs a corrosion- and non-wetting...

2026-02-12

The universally accepted Harmonized System (HS) code for Ceramic Fiber Blankets is 6806.10. This classification falls under “Slag wool, rock wool and similar mineral wools (including intermixtures...

2026-02-11

An aluminum billet is a semi-finished, solid bar of aluminium with controlled internal structure and geometry, produced for downstream forming or machining. In contrast the plain term aluminum refers to...

2026-02-09

Yes. With proper preparation, the right equipment, and strict safety discipline, it is possible to melt and cast aluminum at home for hobby parts, art, or small repairs. Successfully melting and casting...

2026-01-29

While it is physically possible to melt aluminum without flux, doing so in an industrial casting environment is operationally hazardous and detrimental to product quality. Without flux or an equivalent...

2026-01-28

Ceramic foam filters serve a critical role in aluminum casting by removing nonmetallic inclusions, stabilizing melt flow, reducing trapped gas and bifilm defects, and improving mechanical properties and...

2026-01-27

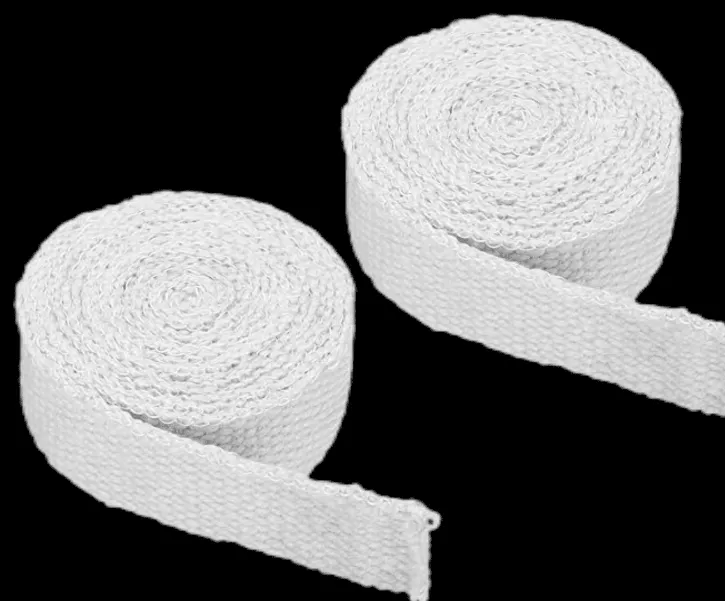

Ceramic Fiber Insulation Tape is a critical thermal management component for aluminum foundries, offering continuous temperature resistance up to 2,300°F (1,260°C). Composed of high-purity alumino-silicate...

No posts found