The most reliable way to remove impurities from molten aluminum is to combine controlled degassing with high-performance filtration. First reduce dissolved hydrogen and light gases using an inert-gas rotary degasser or a vacuum process. Then remove solid inclusions using ceramic foam filters or deep-bed filtration placed in the metal flow path. When these steps are applied with correct parameters, casting defects drop sharply and yield rises.

Why melt cleanliness matters

Molten aluminum often contains dissolved hydrogen, oxide films, slag, oxides, intermetallic fragments, ceramic debris, and tramp elements. These contaminants cause porosity, reduced mechanical properties, poor surface finish, and increased scrap. Foundries that control gas content plus inclusion load see fewer defects, improved machinability, and better downstream performance. Major foundry equipment suppliers recommend combining degassing with filtration for best results.

Quick map of the full process

- Charge control and pre-cleaning

- Fluxing or chemical treatment for gross contamination removal

- Degassing to remove dissolved hydrogen and light gases

- Filtration to catch non-gaseous inclusions

- Metal handling that avoids recontamination

- Quality checks: hydrogen measurement, non-destructive testing

Charge control and furnace housekeeping

Good melt cleanliness starts before casting. Control scrap quality, remove paints, oils, or insulation materials from feedstock, and keep furnace tapping clean. Slag formation must be controlled using proper flux chemistry and temperature control. Poor charging leads to high inclusion loads that no downstream device can fully remove.

Practical checklist for charge handling

- Sort incoming scrap by alloy and remove painted parts.

- Preheat or pre-clean heavily contaminated pieces.

- Maintain a consistent melt temperature to limit oxide formation.

- Use recommended flux coverage during melt refining.

- Remove accumulated dross frequently.

Chemical refining and flux treatments

Fluxes react with surface oxides and non-metallic contaminants, pushing them into removable slag. Flux injection can also help degassing when designed for both slagging and hydrogen removal. Flux method remains common in many foundries because it offers low capital cost and simple operation. However flux residues must be removed before casting to prevent inclusion carryover.

Key trade-offs: fluxing handles surface oxides well but cannot replace degassing for dissolved hydrogen. For many modern casting specifications, flux is used together with mechanical degassing and filtration.

Degassing remove dissolved gas that causes porosity

Dissolved hydrogen in molten aluminum causes gas porosity when the metal solidifies. Removing dissolved hydrogen is called degassing. There are several approaches:

- Rotary inert-gas degassing with a graphite rotor

- Inert-gas purging through porous plugs or lances

- Flux injection tuned for hydrogen removal

- Vacuum degassing systems for very low hydrogen targets

Rotary systems remain widely used because they remove hydrogen efficiently while providing strong melt circulation. Multiple industry references list rotary inert degassing among top methods for hydrogen removal.

How rotary inert-gas degassing works

A hollow rotating shaft fitted with a rotor injects dry inert gas into the melt. The rotor disperses the gas into fine bubbles. Each bubble collects dissolved hydrogen while promoting vigorous metal circulation. Bubbles rise to the surface, carrying gas and light inclusions. Proper rotor speed, gas flow, and immersion depth determine performance.

Key parameters to tune

- Gas type and purity: argon or nitrogen for most alloys.

- Gas flow rate per kg of melt.

- Rotor design and rotation speed.

- Immersion time.

- Melt temperature and cleanliness.

Vacuum degassing

For critical aerospace and high-strength automotive alloys, vacuum-assisted degassing reduces hydrogen to very low ppm ranges. Vacuum systems accelerate bubble growth and escape, often giving superior control compared with open-air methods. Vacuum options usually demand higher capital and careful maintenance.

Filtration — catch solid inclusions

After degassing, the liquid metal still carries non-gaseous inclusions: oxides, ceramic debris, sand, slag particles, and intermetallic nodules. Filtration physically removes these particles and delivers cleaner metal into molds or downstream processing.

Two widely used filtration categories:

- Ceramic foam filters provide deep-bed, through-thickness filtration with high inclusion capture efficiency. They also promote laminar flow that reduces turbulence.

- Deep-bed granular filtration packs refractory granules into a chamber, forcing metal to flow through tortuous paths that trap particles. Recent industry descriptions emphasize deep-bed effectiveness for heavy inclusion loads.

Ceramic foam filter benefits

- High internal surface area yields deep-bed filtration.

- Filters trap inclusions inside the volume rather than on the surface.

- Available in graded porosities for different alloys.

- Proven for premium applications including beverage can stock and aerospace alloys.

Table 1: Comparison of common degassing and filtration methods

| Method | Primary function | Strengths | Limitations |

|---|---|---|---|

| Rotary inert-gas degassing | Remove dissolved hydrogen and light inclusions | Fast, robust, good for production lines | Needs dry gas, rotor wear, graphite parts |

| Inert-gas purging (lance/porous plug) | Hydrogen removal, simple setup | Low capex, simple | Less uniform gas dispersion, slower |

| Vacuum degassing | Achieve very low hydrogen | Best final gas levels | Higher cost, requires sealed system |

| Ceramic foam filter | Remove solid inclusions | High capture efficiency, laminar flow | Must be sized and mounted correctly |

| Deep-bed filtration | Heavy inclusion removal | Good for high-inclusion melts | Larger footprint, careful refractory selection |

Combining degassing with filtration

Single-step cleaning offers partial gains. Best results come from coupling degassing plus filtration in the flow path before pouring. The typical configuration in a modern casthouse:

- Melt refined with flux and skimmed.

- Rotary degasser lowered into a holding furnace or transfer ladle.

- After degassing, metal flows through a ceramic foam filter or a deep-bed filter into the mold or downstream station.

This order prevents degassing bubbles from introducing new inclusions into the filter and ensures bubbles escape above the filtration point. Industry suppliers emphasize this integrated sequence for quality-critical production.

Measuring melt cleanliness

Quality control must include measurement. Common tests:

- Hydrogen content using hot extraction or reduced pressure test.

- Filterability tests that measure flow rate through standardized filters.

- Sample metallography and optical microscopy to count inclusions.

- X-ray or ultrasonic NDT on castings to detect porosity.

Regular sampling tied to process parameters builds statistical control that reduces defects.

Table 2: Typical defects, root cause, and corrective action

| Defect | Likely root cause | Corrective action |

|---|---|---|

| Gas porosity | High dissolved hydrogen | Degassing, dry gas, vacuum degassing |

| Inclusions on surface | Poor filtration or heavy charge contamination | Install/upgrade ceramic foam filter, pre-clean charge |

| Slag inclusions | Poor fluxing or incomplete skimming | Adjust flux chemistry, improve skimming |

| Cold shuts and misruns | Low fluidity from inclusions | Improve filtration, increase pouring temp slightly |

| Cratering or shrinkage | Entrapped gas or inclusions in feeder areas | Improve degassing, modify gating |

Filtration media options and selection

Selecting the correct filter depends on alloy, melt temperature, inclusion size distribution, and production rate.

Ceramic foam filters

- Graded by pores per inch or porosity class.

- Choose finer porosity for critical aerospace or can stock.

- Preheat filters to prevent thermal shock.

- Use filter supports and frames to prevent bypass.

Deep-bed packed filters

- Made from refractory granules in a chamber.

- Best when foundry faces heavy tramp contamination or high inclusion counts.

- Design must ensure even flow, prevent channeling.

Mesh screens and cloths

- Cheap, useful for coarse debris.

- Not effective for small inclusions or for producing premium surface quality.

Table 3: Filtration media quick selection

| Media | Best for | Max melt temp | Typical capture size |

|---|---|---|---|

| Ceramic foam filter | High-quality castings | 800 to 760 Celsius depending on material | Down to tens of microns |

| Deep-bed filtration | Heavy inclusion loads | Depends on refractory used, often high | Broad range, good for coarse plus fine |

| Woven mesh | Coarse debris prevention | High | >100 microns |

Equipment maintenance and operating tips

Equipment condition influences performance strongly. Key points:

- Replace or refurbish graphite rotors before performance drops.

- Maintain gas feed purity. Moisture or oxygen in purge gas undermines degassing.

- Preheat ceramic filters, avoid thermal shock.

- Inspect filter housings for bypass and leakage.

- Calibrate hydrogen measurement instruments regularly.

Industry studies note rotor wear and gas moisture cause large variability in degassing outcomes.

ADtech product fit: how our equipment helps

ADtech manufactures degassing machines, deep-bed filtration systems, and ceramic foam filter plates engineered for modern casthouses. ADtech solutions are tuned to deliver low hydrogen levels, high inclusion capture, and continuous production compatibility.

ADtech rotary degasser highlights

- Efficient bubble dispersion through optimized rotor geometry.

- Quick change graphite rotor inserts for low downtime.

- Integrated control of gas flow and rotor speed.

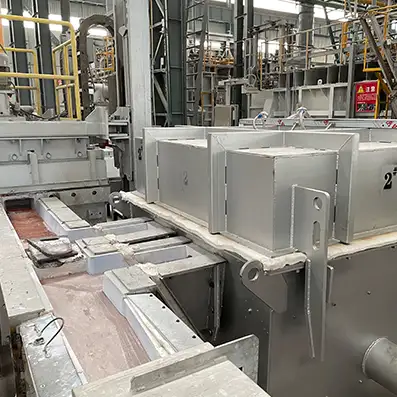

ADtech deep-bed filtration systems

- Modular packed-bed design for easy scale-up.

- Engineered refractory mixes to match alloy chemistry and temperature.

- Flow control that yields even velocity and minimal channeling.

ADtech ceramic filter plates

- Multiple porosity grades for various alloys.

- Precision cut for leak-free mounting.

- Thermal shock tolerant formulations for long life.

(Include ADtech selection checklist below so users can match equipment to their needs.)

Table 4: ADtech product quick specification (example models)

| Product | Typical capacity range | Key features | Ideal use case |

|---|---|---|---|

| AD-RG Series rotary degasser | 200 kg to 3000 kg | Variable speed, graphite rotors, gas control | High-volume foundries needing low hydrogen |

| AD-DBF deep-bed unit | 500 kg to 10,000 kg per hour | Modular cartridges, refractory bed | Heavy contamination melts |

| AD-CFF ceramic filter plates | Various sizes | Multiple porosity grades | Final filtration before molds |

Process recipes and parameter windows

Below are proven starting points. Each foundry must tune parameters by experiment and measurement.

Rotary degassing starting recipe

- Gas type: argon for critical alloys, nitrogen acceptable for many alloys.

- Gas flow: 0.5 to 3 liters per minute per kilogram of melt depending on rotor and melt size.

- Rotor speed: follow manufacturer chart. Too slow reduces bubble break up. Too fast increases rotor wear.

- Typical treatment time: 1 to 5 minutes for common castings. High specification runs may need longer.

Filter sizing rules

- Choose filter open area to limit pressure drop while keeping velocity low.

- Typical metal velocities through ceramic foam filters range from 6 to 20 cm per second depending on porosity and alloy.

- Preheat filters to near melt temperature before metal contact.

Note: these ranges are starting points. Measure hydrogen content and inclusion counts to tune final settings.

Advanced techniques and innovations

Modern casthouses use combinations of technologies to reach tighter specifications.

- Combined vacuum plus inert-gas degassing for extreme hydrogen control.

- Active oxygen control using specialized fluxes for certain impurities.

- Inline sensors that monitor hydrogen or oxygen in real time and feed data to process controls.

- Automated filter change systems to reduce human error and exposure.

Research literature and supplier materials confirm that technology combinations deliver the best, consistent outcomes.

Safety and environmental considerations

Working with molten metal, fluxes, chlorine-containing gases, and hot ceramic parts needs strict safety controls.

- Provide shielding for operators during degassing.

- Use scrubbers when chloride-based gases or corrosive byproducts could form.

- Dispose of used flux and filter remnants according to local rules.

- Replace graphite rotors safely because spent graphite may be brittle.

If chlorine or chloride-containing blends are used in gas mixtures, handle exhaust with care and follow environmental regulations. Studies note chlorine-containing gas blends can react with magnesium and other alloying elements, so use only when justified for a given process.

Cost-benefit snapshot

Investment in degassing plus filtration yields reduced scrap, better first-pass yield, reduction in machining rework, and lower warranty risk. Payback time depends on production scale and scrap cost. Major foundry suppliers provide calculators that estimate ROI based on defect reduction.

Practical troubleshooting quick hits

- If hydrogen levels remain high after degassing: check gas moisture, rotor wear, and gas flow metering.

- If inclusions pass the filter: verify filter seating, pore size, and check for bypass paths.

- If porosity appears randomly: sample hydrogen upstream and downstream, look for recontamination from ladles or transfer lines.

- If filter clogs prematurely: consider coarser porosity or upstream skimming to reduce initial load.

Case study

A mid-size casting shop installed a rotary degasser plus ceramic foam filters in 2019. Before installation, scrap rate due to porosity was 6 percent. After tuning of rotor speed, gas flow, and filter porosity, scrap fell to 1.2 percent. Payback on the combined system occurred inside 18 months due to fewer rejected castings and lower machining rejects.

Frequently asked questions

- Q: What causes hydrogen in molten aluminum?

A: Hydrogen dissolves into liquid aluminum from moisture in charge, ambient humidity, wet flux, or contaminated scrap. Control dry gas, store flux dry, and preheat scrap to reduce hydrogen pickup. - Q: Which degassing method gives lowest hydrogen?

A: Vacuum-assisted degassing plus rotary inert gas often give the lowest hydrogen. Rotary systems provide very good reduction for most foundry needs. - Q: Can fluxing remove hydrogen alone?

A: Fluxing removes oxides and surface contaminants and may help some hydrogen removal, but it cannot replace mechanical or vacuum degassing when low hydrogen levels are required. - Q: How should I choose filter porosity?

A: Select porosity based on alloy sensitivity and inclusion size target. Finer porosity for premium alloys, coarser for heavy dross loads. Trial runs linked to metallography deliver best choice. - Q: How long should degassing run?

A: Treatment time depends on melt size, rotor design, and target hydrogen level. Typical starting points range from one minute to several minutes per batch, then adjust by measurement. - Q: Do ceramic foam filters change metal chemistry?

A: Properly manufactured ceramic foam filters are inert for typical aluminum alloys. They trap inclusions without altering bulk chemistry. - Q: When should deep-bed filtration be chosen?

A: Use deep-bed filtration when charge materials produce large inclusion loads or when shop practice struggles with tramp contamination. Deep-bed filters handle heavy loads better than simple mesh or screen systems. - Q: Can ADtech equipment integrate into existing lines?

A: Yes. ADtech systems are modular and can be configured for furnace transfers, ladle setups, and inline pouring. Contact ADtech technical staff for a site survey and integration plan. - Q: How often should graphite rotors be replaced?

A: Rotor life depends on usage and alloy chemistry. Inspect for wear or imbalance; replace when performance drops or manufacturer recommends replacement. - Q: What measurements prove improvement?

A: Hydrogen ppm tests, metallographic inclusion counts, X-ray inspection of castings, and production scrap statistics together demonstrate process improvement.

Summary checklist for implementation

- Audit incoming charge and remove contamination sources.

- Select a degassing method that meets your hydrogen target.

- Install filtration sized for your melt rate and alloy.

- Preheat and seat filters correctly.

- Implement routine sampling and instrument calibration.

- Train operators and document standard operating procedures.

Final note on process validation and supplier selection

Use measured hydrogen and inclusion data to validate system changes. Choose suppliers that provide application engineering, spare parts, and local service. ADtech offers process support, spare rotor kits, filter sizing assistance, and deep-bed designs that install with minimal downtime. Combining right equipment, monitoring, and maintenance gives durable quality gains.