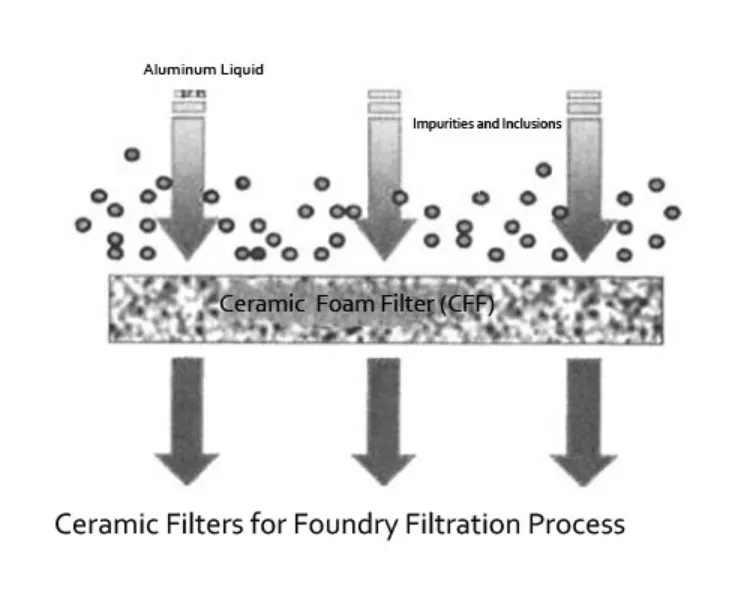

Ceramic foam filters serve a critical role in aluminum casting by removing nonmetallic inclusions, stabilizing melt flow, reducing trapped gas and bifilm defects, and improving mechanical properties and surface finish of castings; when properly selected and installed they lower scrap rates, enable consistent process control, and provide a high return on investment for foundries producing structural, automotive, aerospace, and high-quality consumer components.

What primary roles do ceramic foam filters perform in aluminum and nonferrous casting?

Ceramic foam filters act as a physical barrier that traps nonmetallic particles and modifies flow to produce a steadier, laminar metal front entering the mold. In practical terms this means fewer inclusions in final parts, fewer surface defects, reduced porosity, and a quieter gating system with lower turbulence that reduces the formation of double-oxide bifilms. By removing solid and semi-solid inclusions and by damping flow energy they protect downstream tooling and improve fill behavior for complex geometries.

Also read: Ceramic Foam Filter Manufacturing Process.

Beyond particle capture and flow conditioning, filters can assist in reducing entrapped hydrogen and other gases indirectly because a less turbulent metal flow causes fewer gas entrapment events and helps coalescence of microbubbles upstream of the mold. Properly matched ceramic foam filtration often becomes a standard process control element for foundries producing load-bearing castings where repeatable mechanical properties are required.

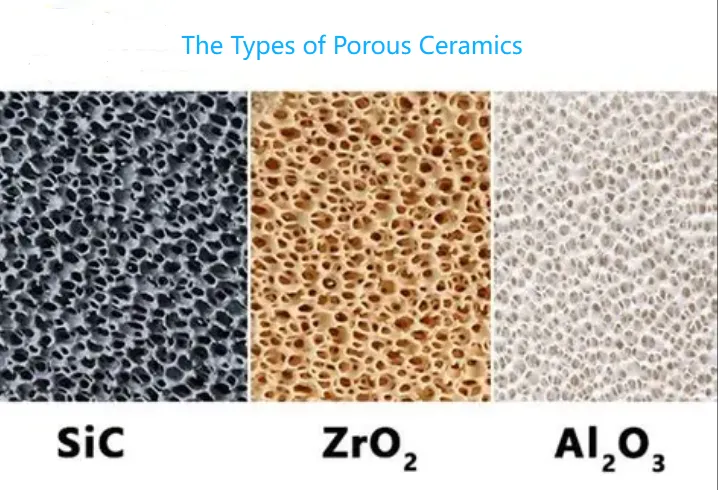

Which materials and manufacturing grades are available, and how do they affect performance?

Ceramic foam filters are manufactured from several refractory chemistries, each optimized for temperature, chemical compatibility, and mechanical strength. The main families in commercial foundry use are:

-

High-purity alumina based filters, often phosphate bonded. These provide excellent chemical stability in molten aluminum and good mechanical strength. Typical operating temperatures suit aluminum and many nonferrous alloys.

-

Silicon carbide and silicon carbide containing composites for iron and higher temperature applications. They offer higher thermal shock resistance and mechanical robustness for ferrous metal filtration.

-

Zirconia and stabilized-zirconia blends for extreme chemical resistance and abrasion resistance.

-

Mixed alumina-silica products for cost-performance balance.

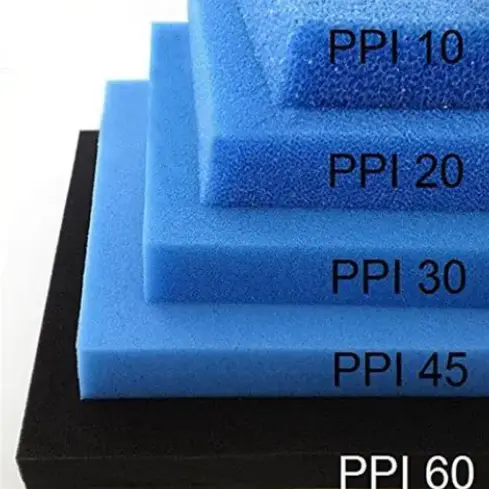

Filter performance is commonly specified by pore density (PPI, pores per inch), cell/window sizes, porosity, permeability and compressive strength. Manufacturers publish grades (for example 10 to 80 PPI) where lower PPI means coarser pores and higher flow capacity, while higher PPI gives finer filtration and greater inclusion capture but increases pressure drop. Selecting the correct chemistry and grade balances inclusion capture, pressure drop, and mechanical robustness during pouring.

How do ceramic foam filters capture inclusions? Filtration mechanisms explained

Filtration inside a ceramic foam filter is not a single physical event but a combination of mechanisms acting across the porous network:

-

Inertial impaction: Larger inclusions with momentum deviate from streamlines and collide with ligament surfaces inside the filter.

-

Interception: Particles following streamlines that pass close to ligaments contact and adhere to the surface.

-

Diffusion and Brownian motion: For sub-micron particles there is a small, but sometimes relevant, contribution from Brownian movement leading to surface contact.

-

Depth capture and straining: Ceramic foam filters operate in deep-bed mode. Particles become lodged within multiple planes throughout the filter thickness, not only at the surface. This distributes the captured mass over the filter volume, extending useful life before clogging.

Two consequences follow from these modes. First, capture efficiency depends strongly on particle size distribution and flow velocity. Second, because capture occurs within a volume, filters can trap a high mass fraction before causing problematic pressure drop, making them highly suitable for continuous pours and large castings.

How does filter pore structure and hydraulic behavior control filtration effectiveness?

The hydraulic behavior of ceramic foam filters is determined by porosity, window diameter, and cell geometry. These microstructural features set the permeability and pressure drop for a given flow rate. Key observations from experimental studies are:

-

Permeability is inversely related to pressure drop; coarser filters yield lower pressure drop for a fixed flow rate but lower capture efficiency for fine inclusions.

-

Flow regime in typical aluminum casting — often laminar to transitional — means that increasing pore density (higher PPI) reduces local Reynolds numbers inside cells and improves capture of smaller inclusions.

-

Manufacturers and independent researchers measure permeability and pressure drop across grades to provide engineers with data for gating design and to avoid excessive fill pressure or flow-induced defects.

When designing the gating system, engineers use pressure-drop vs flow rate curves supplied by filter vendors or measured in-house. This provides the basis for selecting pore size and thickness to meet both metallurgical cleanliness targets and practical pouring constraints.

How should ceramic foam filters be selected and placed within gating systems?

Filter selection and placement are equally important. Good practice recommendations for aluminum foundries include:

-

Place the filter upstream of the mold in the runner or filter box so the metal flow first encounters the filter. Horizontal placement often yields better laminar filling for certain mold geometries because it reduces direct impact forces on the filter.

-

Choose filter area and thickness to keep pressure drop below a fraction of available head so filling time and gating velocity remain within design limits. Avoid excessive compressive loads or direct impact on small filters.

-

Use gaskets and correct seat geometry to prevent metal bypass around the filter edge which would render the filtration ineffective. Many suppliers provide matched gaskets and filter frames to ensure a proper seal.

-

For high-risk castings consider dual-stage filtration, where a coarser pre-filter removes large slag and a finer secondary filter polishes the melt.

A classic reason for poor filtration performance is incorrect orientation or insufficient seating that allows molten metal to bypass the filter. Another common mistake is picking a filter that is too fine for the pouring rate, causing premature clogging and turbulence.

Video Introduction: Alumina ceramic foam filter plate is used for aluminum casting.

What measurable benefits do foundries obtain from ceramic foam filtration?

Using ceramic foam filters yields multiple measurable gains across quality, yield, and process reliability:

-

Reduced inclusion-related defects leading to lower scrap or rework rates. Typical case studies show significant reductions in inclusion-driven rejects for structural components.

-

Improved mechanical properties, notably increased elongation and reduced scatter in tensile results, because inclusions and bifilms act as stress concentrators.

-

Improved surface finish, reducing machining allowances and finishing costs.

-

Less tool wear and fewer gating blockages, because larger inclusions are removed upstream.

-

Process stability, because filters temper the velocity profile and reduce sensitivity to small variations in pouring rate.

Economically, the cost of the filter is typically small relative to the yield improvement for medium and high-value castings. Many foundries report payback in a few dozen to a few hundred casts depending on product value and initial defect rate.

Common installation errors and troubleshooting

Typical issues and corrective actions:

-

Bypass at edges: Ensure gasket and seat are correct size. If bypass is detected, check for thermal warping of the filter frame and change to rigid retained frames if needed.

-

Filter fracture during pouring: Check impact velocity and consider thicker filters or staged pre-filters. Use horizontal mounting where appropriate to spread impact.

-

Premature clogging: If the filter blocks too early, either the filter is too fine for the melt cleanliness or pour rate, or the melt contains excessive oxides/slag. Pre-cleaning flux, degassing, or a coarser pre-filter can resolve this.

-

Insufficient inclusion removal: Verify correct filter grade, absence of bypass, and that the filter is placed upstream of any turbulent device or choke in the runner.

Many foundries keep a simple filter performance log that records filter grade, pour rate, casting geometry, and defect rate. Over a few weeks this data identifies systematic mismatches between filter grade and process.

Test methods, standards and validation for filter performance

Process and product engineers use a combination of lab and shop floor tests:

-

Pressure-drop vs flow rate curves for engineered gating designs help avoid excessive backpressure. These are often measured using water tests scaled to metal density or with controlled molten metal trials.

-

Metallographic inspection of filter-captured inclusions and of cross-sections of castings to quantify inclusion area fraction and size distribution.

-

Mechanical testing for tensile strength, elongation, and fatigue where required by design codes.

-

Cleanliness indices such as phase contrast microscopy and automated image analysis for inclusion counts and sizes.

-

Process capability analysis comparing defect rates before and after filtration to provide an economic justification.

Standards bodies do not yet have a single global standard for ceramic foam filter grades; practical vendor data sheets and independent hydraulic characterization studies are therefore crucial to set expectations and validate performance in-house.

Comparative table: common filter chemistries and typical foundry applications

| Material chemistry | Typical melting / operating range | Best-suited metals | Strengths | Limitations |

|---|---|---|---|---|

| High-purity alumina (Al2O3, phosphate bonded) | up to 1200°C and higher for short exposure | Aluminum, Al alloys, some nonferrous | Excellent chemical compatibility with Al, good mechanical strength, cost-effective | Not ideal for high-carbon ferrous melts |

| Silicon carbide (SiC) | up to 1600°C | Cast iron, steel, some niche nonferrous | High thermal shock resistance, abrasion resistance | Higher cost for some geometries, reactive with some alloys |

| Zirconia based | very high temperature stability | Specialized ferrous and niche alloys | Exceptional chemical resistance and mechanical toughness | Highest cost, used where other chemistries fail |

| Mixed alumina-silicate | moderate to high | General nonferrous | Balanced cost and performance | Intermediate chemical resistance |

(Source: manufacturer product line summaries and independent materials reviews).

Typical grade table: PPI, approximate window size, and common use cases

| Grade (PPI) | Approx. window diameter (µm) | Typical application in aluminum casting |

|---|---|---|

| 10 PPI | 3000–5000 | Coarse pre-filter for heavy slag removal or very high flow rates |

| 15 PPI | 2000–3500 | General purpose: large castings with moderate cleanliness needs |

| 25 PPI | 1000–2000 | Standard finishing filter for many structural aluminum castings |

| 30–40 PPI | 500–1200 | Fine filtration for critical parts requiring high elongation and surface finish |

| 50–80 PPI | <500 | Laboratory or specialty applications; increased pressure drop |

Data are indicative and depend on manufacturer definitions of PPI and porosity. Always validate using vendor permeability and pressure-drop data.

Practical procurement and process-engineering selection checklist

-

Define cleanliness targets and allowable inclusion sizes by metallurgical analysis.

-

Record expected pour rate and available head at the filter seat.

-

Request permeability and pressure drop curves from suppliers for candidate grades.

-

Select filter chemistry compatible with alloy chemistry and operating temperature.

-

Design filter seat and gasket to prevent bypass; verify frame stiffness at operating temperature.

-

If using multiple shifts or long runs, evaluate filter mass capture capacity and plan replacement intervals.

-

Run a controlled trial with pre- and post-filter sampling, metallography, and mechanical testing.

-

Log outcomes and optimize grade/area combination for cost vs yield.

Economic case examples

A mid-size foundry producing automotive suspension parts reported the following simplified example: baseline scrap due to inclusion-related defects of 4% reduced to 1.5% after implementing ceramic foam filtration combined with minor gating redesign. The increase in process cost per casting from filters and frames was offset within several weeks because the reduction in scrap and rework yielded net savings. Actual returns depend on part value, cycle time, and defect costs; companies should run a short controlled pilot to quantify benefits in their specific environment. Manufacturer data and independent studies support sizeable ROI for medium and high-value castings when filtration is correctly implemented.

Research advances and what engineers should watch for

Recent experimental work focuses on hydraulic characterization, additive manufacturing routes for tuned pore geometries, and composite chemistries that improve toughness while providing finer filtration. The scientific literature is quantifying permeability, pressure-drop behavior, and capture efficiency across grades, giving engineers better predictive tools for gating design. Performance is being optimized by pairing filtration with upstream melt conditioning such as degassing and skimming to reduce the load placed on filters.

Best practices summary for process control

-

Combine filtration with routine melt cleaning steps: fluxing, degassing, and skimming.

-

Use filter grades matched to predicted inclusion spectrum and pour rate.

-

Ensure mechanical seating and proper gasketing to avoid bypass.

-

Record and analyze filter performance data and casting quality metrics over time.

-

Consider staged filtration in high-inclusion environments.

These practices make filtration a predictable and dependable element of quality control.

Table: Quick troubleshooting matrix

| Symptom | Likely cause | Action |

|---|---|---|

| Little or no reduction in inclusions | Bypass at edges or wrong placement | Inspect seating, change gasket, reposition filter |

| Filters clog quickly | Filter too fine or high oxide load | Use coarser pre-filter, improve upstream melt cleaning |

| Filter fractures | High impact velocity or thermal shock | Thicker filter or horizontal mounting, reduce gating velocity |

| Variability in casting quality | Inconsistent pouring rate or filter grade | Standardize pour parameters, use same lot filters |

Ceramic Foam Filters (CFF): Technical FAQ

1. What is the single most important benefit of using ceramic foam filters?

2. Do ceramic foam filters remove dissolved gases like hydrogen?

3. How often should a filter be changed during continuous pouring?

4. Is a finer filter (higher PPI) always better?

5. Can ceramic foam filters be re-used?

6. Which filter chemistry is best for aluminum alloys?

7. How should filters be seated to prevent bypass?

8. Do filters affect fill time or gating design?

9. Are there environmental or handling safety concerns?

10. What validation steps should be taken before full-scale adoption?

Closing recommendations for engineers and procurement

To implement ceramic foam filtration successfully:

-

Conduct a targeted pilot with baseline and post-installation measurements for both metallurgical cleanliness and part performance.

-

Request permeability and pressure-drop data from suppliers, and demand trial samples for shop-floor validation.

-

Integrate filtration decisions into gating design calculations to control velocity and avoid bifilm formation.

-

Maintain logs linking filter grade, pour parameters, and casting defects, then iterate until optimal grade and area are identified.

-

Consider supplier technical support and service agreements for first installations; many vendors provide application engineering assistance.