Launder System

Products

PRODUCTS

CONTACT US

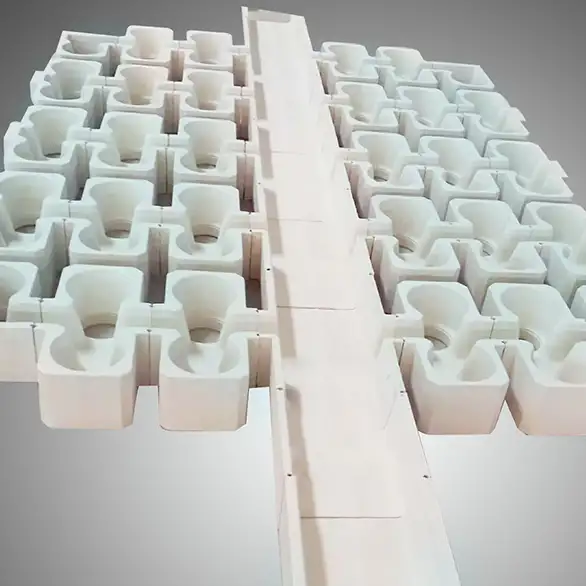

The Launder system, designed specifically for use in aluminum plants, includes a variety of key products crucial for managing molten aluminum transport and distribution processes. The product range includes the Integrated Aluminum Liquid Launder System, Troughs, Launder Dams, and Distribution Launders. These components are engineered to facilitate the safe, efficient, and precise movement of molten aluminum through various stages of production. Their advanced designs contribute significantly to reducing energy consumption, enhancing safety, and improving process control in aluminum foundries and casting operations.

1. Introduction to Launder Systems

Launder systems play a pivotal role in the operation of aluminum plants. These systems are designed to transport and distribute molten aluminum from the furnace to casting machines, ensuring that the metal flows smoothly and efficiently without contamination or excessive loss of heat. By incorporating advanced features such as insulated components and customizable configurations, the Launder series provides optimal solutions for controlling molten metal flow in a highly demanding industrial environment.

Key features of the Launder series include precision-engineered troughs, durable launder dams, and efficient distribution launder systems, all of which are built to withstand the high temperatures and aggressive conditions typical in aluminum manufacturing. These systems not only enhance the performance of aluminum plants but also contribute to energy savings and improved safety for workers.

2. Integrated Aluminum Liquid Launder System

Design and Functionality

The Integrated Aluminum Liquid Launder System is a comprehensive solution that ensures the efficient movement of molten aluminum from one part of the plant to another. It consists of interconnected launder components that include troughs, dams, and distribution units, forming a seamless network. The system is designed to minimize the risk of contamination and metal loss by providing a stable and controlled flow path.

The integration of various components into one unified system makes it easier to install, operate, and maintain. The system is also designed with insulation to minimize heat loss, which is critical in maintaining the temperature of the molten aluminum.

Installation and Operation Guidelines

When installing the Integrated Aluminum Liquid Launder System, it is essential to ensure that all components are properly aligned to prevent leaks or blockages. A thorough inspection of the system before commissioning is necessary to confirm that all seals and joints are secure. During operation, regular monitoring of the metal flow and temperature is crucial to ensure that the system is functioning optimally.

Benefits in Aluminum Plant Operations

The Integrated Aluminum Liquid Launder System offers several advantages, including:

-

Energy Efficiency: The design minimizes heat loss during transport, reducing the energy required to keep the aluminum molten.

-

Enhanced Safety: The integrated system ensures stable and predictable metal flow, reducing the risk of accidents caused by sudden metal splashes or spills.

-

Reduced Contamination: By providing a sealed system, the integrated launder minimizes the risk of introducing impurities into the molten aluminum.

3. Launder Troughs

Design Features and Materials

Launder troughs are essential components of the molten metal transport system. These troughs are typically constructed from high-temperature resistant materials, such as stainless steel or refractory-lined metals, to ensure durability in the harsh conditions found in aluminum plants. The troughs are designed to withstand not only the high temperatures of molten aluminum but also the physical stresses associated with the metal’s flow.

Application in Molten Metal Transfer

Launder troughs are used to transport molten aluminum between different sections of the plant. They are often custom-built to fit the specific layout of the plant and can be equipped with insulating materials to maintain the molten aluminum’s temperature over long distances.

Best Practices for Maintenance

Regular maintenance of launder troughs is vital to ensure their longevity and optimal performance. The key maintenance activities include:

-

Inspecting for Wear and Tear: Over time, troughs can develop cracks or other forms of wear. Regular inspections help identify these issues early.

-

Cleaning and Deslagging: Molten aluminum can leave behind residues that accumulate in the troughs. Periodic cleaning is necessary to avoid blockages and ensure a continuous flow.

-

Checking for Leaks: Seals and joints should be regularly checked for leaks, which can cause both metal loss and safety hazards.

4. Launder Dams

Functionality and Purpose in Controlling Molten Metal Flow

Launder dams are designed to regulate the flow of molten aluminum, preventing it from flowing uncontrollably and causing spills. By strategically placing launder dams in key areas, plant operators can control the metal’s direction and ensure that it flows into the correct casting molds or areas for further processing.

Design Innovations for Enhanced Safety

Launder dams are typically designed with a focus on safety, including features such as heat-resistant coatings and easily adjustable components to allow for quick changes in the flow direction. Some designs also include mechanisms for quick-release in case of emergency situations, ensuring that the molten metal can be diverted away from hazardous areas.

5. Distribution Launder

Role in Ensuring Even Metal Distribution

The distribution launder is critical for ensuring that molten aluminum is evenly distributed to multiple casting molds or other processing areas. By using a distribution launder, operators can ensure that each mold receives the appropriate amount of metal, preventing defects such as cold spots or incomplete filling.

Types and Design Variations

Different types of distribution launders are available, depending on the size of the operation and the specific needs of the plant. Some designs incorporate adjustable gates or flow distributors to further refine the flow of molten metal. The choice of design depends on factors such as the volume of aluminum being processed and the layout of the plant.

6. Safety and Maintenance Considerations

Common Maintenance Issues and Troubleshooting

While launder systems are designed to be durable and low-maintenance, operators should be aware of common issues such as:

-

Thermal Expansion: Prolonged exposure to high temperatures can cause the launder components to expand and contract. This can lead to misalignment or stress fractures.

-

Blockages: Solidified aluminum or debris can block the flow of molten metal, leading to slowdowns or interruptions in production.

To troubleshoot these issues, plant operators should regularly monitor the system for signs of wear or damage and perform necessary repairs promptly.

Ensuring Worker Safety During Launder Operation

Safety is paramount when operating launder systems. Proper training for workers is essential to prevent accidents involving molten metal. Additionally, ensuring that the system is equipped with emergency shut-off valves, heat shields, and safety barriers will help reduce the risk of injuries.

7. FAQs

What materials are used to construct launder troughs?

Launder troughs are typically made of stainless steel or refractory-lined metals to withstand high temperatures.

How do launder systems help improve energy efficiency?

By minimizing heat loss during metal transfer, launder systems help reduce the energy needed to maintain the molten aluminum’s temperature.

What is the purpose of launder dams in an aluminum plant?

Launder dams regulate the flow of molten aluminum, preventing uncontrolled spills and ensuring that the metal flows to the correct area.

How often should launder systems be cleaned?

Launder systems should be cleaned periodically to remove residues and prevent blockages.

Can launder systems be customized for specific plant layouts?

Yes, launder systems are often customized to fit the specific needs and layout of an aluminum plant.

What safety features are included in launder systems?

Launder systems include heat-resistant coatings, emergency shut-off valves, and adjustable components for controlling metal flow.

What are the most common maintenance issues with launder systems?

Common issues include thermal expansion, blockages, and wear and tear on seals and joints.

How can I troubleshoot a blocked launder system?

Inspect for debris or solidified metal causing the blockage and remove it. Regular maintenance helps prevent such issues.

What is the role of a distribution launder?

A distribution launder ensures that molten aluminum is evenly distributed across multiple casting molds or processing areas.

How do you ensure molten aluminum stays at the right temperature during transport?

By using insulated components and minimizing the distance the metal travels, launder systems help maintain the metal’s temperature.

8. Conclusion

The Launder series, consisting of the Integrated Aluminum Liquid Launder System, troughs, launder dams, and distribution launders, is an essential suite of products for aluminum plants. These systems provide safe, efficient, and energy-conscious solutions for transporting molten aluminum across the production facility. Proper installation, maintenance, and operation of launder systems are crucial for optimizing plant performance and ensuring worker safety. Through careful selection of materials and design considerations, aluminum plants can significantly improve their casting operations while reducing environmental impact and enhancing operational efficiency.