Flow Control Series

Products

PRODUCTS

CONTACT US

The Flow Control Series is a critical component designed specifically for aluminum manufacturing facilities, offering a suite of advanced solutions that significantly enhance the efficiency and precision of aluminum production processes. Key products within this series include the Flow Control Bar, Flow Tube, Flow Pipe & Float Plate, Impurity Separation Ring, Tap Out Cone, Graphite Cone, and ceramic wire rods. These tools and devices play a pivotal role in ensuring optimal metal flow management, impurity separation, and labor-saving processes, all of which are tailored exclusively for aluminum plants. This series of flow control products helps mitigate common operational challenges such as the prevention of impurities in molten aluminum, ensuring smoother casting operations, and enhancing overall productivity in aluminum processing.

1. Overview of the Flow Control Series for Aluminum Plants

The Flow Control Series is an essential part of any modern aluminum plant, providing specialized equipment that ensures optimal fluid dynamics in various stages of aluminum production. These devices are built to withstand the high temperatures and harsh conditions typical of aluminum smelting and casting processes, offering both durability and precision.

-

Flow Control Bar and Flow Tube: These components are integral for controlling the molten metal’s flow during the casting process. Their primary function is to ensure a steady, regulated flow of molten aluminum, preventing overflow and ensuring the desired quality in the final casted product.

-

Flow Pipe and Float Plate: The Flow Pipe and Float Plate are designed to further streamline the metal delivery process, with the Float Plate providing stability and balance to the flow of molten metal as it enters the casting mold. This combination ensures even distribution, which is crucial for the uniformity of the aluminum products.

-

Impurity Separation Ring: Impurities in molten aluminum, such as oxides and inclusions, can significantly affect the quality of the finished product. The Impurity Separation Ring is designed to remove such contaminants, ensuring a cleaner and purer aluminum output.

-

Tap Out Cone and Graphite Cone: These devices are critical in the tapping process, which involves the controlled release of molten aluminum from the furnace or holding vessel. The Tap Out Cone, often paired with the Graphite Cone, helps guide the molten metal precisely into the casting mold, minimizing spillage and contamination.

-

Ceramic Wire Rod: The Ceramic Wire Rod made from advanced materials offers superior strength and high thermal resistance, making it ideal for high-temperature aluminum casting processes. Its successful use in various aluminum plants underscores its effectiveness in reducing wear and tear on equipment.

-

Discharge Device for Residual Aluminum: This device is particularly useful in ensuring that any leftover molten aluminum is effectively utilized, reducing waste. It is an eco-friendly, labor-saving solution that improves operational efficiency by reducing the amount of residual aluminum that needs to be disposed of.

2. Importance of Flow Control in Aluminum Production

Effective flow control in aluminum manufacturing is crucial for achieving consistent product quality, reducing waste, and optimizing production efficiency. The nature of aluminum as a molten metal requires highly specialized equipment to manage its flow during casting, which can otherwise result in defects, spills, or impurities. By implementing a comprehensive flow control strategy, aluminum plants can:

-

Reduce Defects: Proper flow management reduces the risk of defects such as cracks, inclusions, or inconsistent thickness in the final product.

-

Improve Yield: Efficient use of molten aluminum minimizes waste, leading to better material usage and overall cost savings.

-

Enhance Process Efficiency: Automated and precise control over the metal flow allows for faster processing times, leading to higher throughput in the casting process.

-

Energy Efficiency: Managing molten metal flow effectively helps reduce energy consumption by minimizing temperature fluctuations and reducing unnecessary reheating.

3. Detailed Breakdown of Flow Control Series Components

Flow Control Bar and Flow Tube

Function: These components control the movement of molten aluminum from the furnace to the casting area, ensuring a consistent, smooth flow.

Materials: Constructed from high-quality, heat-resistant alloys to withstand extreme temperatures.

Applications: Used primarily in continuous casting and casting of aluminum billets, sheets, and slabs.

| Feature | Description |

|---|---|

| Temperature Resistance | Up to 1,000°C (1832°F) |

| Material Composition | Heat-resistant alloys, customized for molten aluminum |

| Flow Control Precision | Provides controlled flow, preventing overflow and spillage |

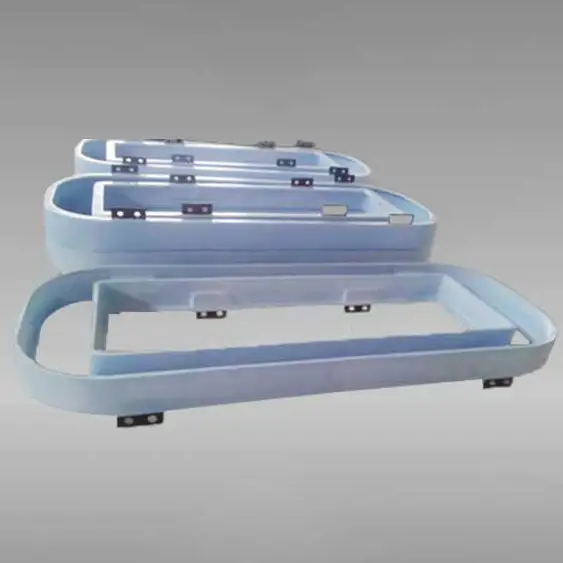

Flow Pipe & Float Plate

Function: These elements ensure that molten aluminum is delivered to the casting mold at a controlled speed and with balanced pressure.

Materials: Made from heat-resistant metals and reinforced ceramics for durability.

Benefits:

-

Enhanced Casting Efficiency: Ensures a steady flow, reducing variations in aluminum quality.

-

Precise Distribution: Promotes even flow distribution to avoid uneven solidification.

| Feature | Description |

|---|---|

| Float Plate Material | Reinforced ceramics or high-strength alloys |

| Pressure Resistance | Designed for sustained high-temperature operations |

| Design Innovation | Streamlined for improved metal delivery |

Impurity Separation Ring

Function: The Impurity Separation Ring is employed to remove non-metallic impurities from the molten aluminum.

Working Principle: The ring creates a filtration barrier that captures oxides and other inclusions before the metal reaches the mold.

Impact on Product Quality: Reduces the risk of casting defects caused by inclusions, ensuring higher quality final products.

| Feature | Description |

|---|---|

| Filtration Efficiency | High-efficiency impurity removal system |

| Material | High-purity ceramics or specialized composites |

| Applications | Used in aluminum smelting and casting processes |

Tap Out Cone and Graphite Cone

Function: These components manage the tapping of molten aluminum from the furnace to the casting area.

Role in Casting: The cones ensure that the flow of aluminum is precise and stable, minimizing metal waste and contamination during the tapping process.

| Feature | Description |

|---|---|

| Graphite Cone Quality | High thermal conductivity and resistance to corrosion |

| Tap Control Precision | Minimizes overflow and contamination |

Ceramic Wire Rod

Function: A high-strength material used to provide structural integrity to the flow control system.

Usage: The Ceramic Wire Rod is used in parts of the flow control system that need to withstand extreme temperatures without breaking down.

| Feature | Description |

|---|---|

| Strength | High tensile strength under high-temperature conditions |

| Thermal Resistance | Withstands up to 1,200°C (2192°F) |

| Durability | Long-lasting with minimal wear and tear |

Discharge Device for Residual Aluminum

Function: This device is designed to collect and reuse residual aluminum, making the most out of every melt cycle.

Benefits: By saving labor and reducing aluminum waste, this device contributes to both operational efficiency and cost savings.

| Feature | Description |

|---|---|

| Waste Reduction | Minimizes aluminum waste during the casting process |

| Labor Efficiency | Reduces manual labor in handling residual aluminum |

| Environmental Impact | Eco-friendly solution by recycling residual molten aluminum |

4. The Role of Flow Control in Enhancing Aluminum Plant Efficiency

Efficient flow control plays a crucial role in boosting productivity in aluminum plants. By managing the flow of molten metal more effectively, these devices prevent costly mistakes and interruptions during the casting process. Here are some key benefits:

-

Reduced Downtime: The precise flow management reduces the chances of equipment failure or unexpected delays.

-

Better Resource Utilization: By ensuring that molten metal is effectively used, waste is minimized, and the overall cost of production is reduced.

-

Improved Worker Safety: A more controlled and predictable flow reduces the risk of accidents related to molten metal spillage.

5. FAQs

-

What is the Flow Control Series used for?

The Flow Control Series is designed specifically for aluminum plants to manage molten aluminum flow, remove impurities, and reduce waste. -

What is the primary material used in these products?

The products are made from heat-resistant alloys, ceramics, and graphite to withstand high temperatures. -

Can these products be used in other industries?

These products are specifically designed for aluminum plants and may not be suitable for other industries. -

How does the Impurity Separation Ring work?

The ring filters out non-metallic impurities from the molten aluminum, ensuring a purer final product. -

What is the role of the Ceramic Wire Rod in the flow control system?

The Ceramic Wire Rod provides structural support in high-temperature areas of the flow control system. -

How does the Tap Out Cone help in aluminum casting?

The Tap Out Cone helps precisely control the release of molten aluminum from the furnace, preventing overflow. -

What are the environmental benefits of the Discharge Device?

It reduces aluminum waste by collecting and reusing residual molten aluminum, contributing to more sustainable operations. -

Can these flow control products improve casting quality?

Yes, they help maintain consistent molten metal flow, reducing defects and ensuring higher quality casts. -

Are there any safety concerns with these products?

As these products are designed for high-temperature applications, proper handling and maintenance are necessary to ensure safety. -

How can these products increase productivity in aluminum plants?

By reducing waste, improving flow precision, and reducing downtime, these products enhance overall production efficiency.

6. Conclusion

The Flow Control Series is an indispensable set of tools for any modern aluminum plant. Its components work synergistically to optimize molten aluminum flow, reduce impurities, and minimize waste, all while ensuring that casting operations are efficient, safe, and environmentally friendly. The specialized nature of these products makes them an ideal solution for managing the unique challenges faced by aluminum manufacturers, ultimately contributing to improved product quality, lower operational costs, and a more sustainable production process.