Filter Purification Series

Products

PRODUCTS

CONTACT US

The quality and purity of aluminum are crucial factors in its application across various industries, particularly in aerospace, automotive, and manufacturing. In aluminum production, effective filtration systems are vital for removing impurities from molten aluminum, ensuring optimal performance and preventing defects in the final products. The Filter Purification Series plays a pivotal role in improving aluminum production by utilizing advanced filtration technologies, including Ceramic Foam Filters, Deep Bed Filtration Equipment, and Tubular/Cartridge Filter Equipment. These systems are designed to meet the demanding requirements of aluminum smelters, offering superior filtration capabilities and enhancing the efficiency of the overall production process.

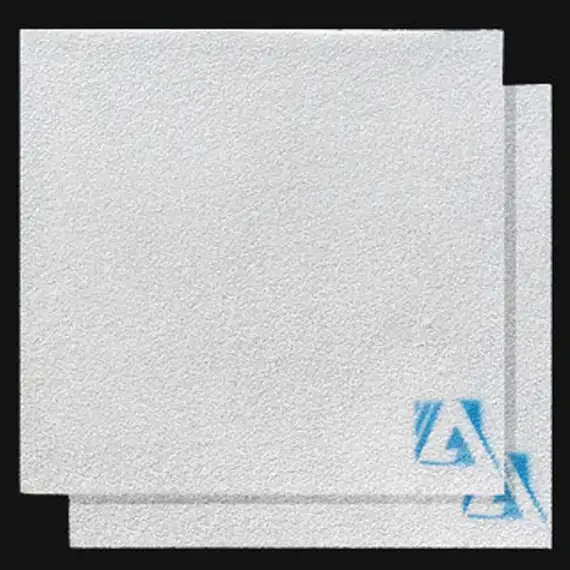

1. Ceramic Foam Filters

Overview

Ceramic foam filters are integral to the Filter Purification Series, offering an efficient solution for removing impurities in aluminum and other non-ferrous metals. These filters are designed to trap both particulate contaminants and non-metallic inclusions, ensuring high-quality metal output. Made from high-performance ceramic materials, they are engineered to withstand the high temperatures of molten aluminum while maintaining structural integrity.

Properties and Advantages

-

High Temperature Resistance: Ceramic foam filters can endure temperatures of up to 1600°C, making them suitable for filtering molten aluminum.

-

Fine Filtration: These filters provide fine porosity that allows them to remove even the smallest impurities, such as oxides and slag.

-

Durability: Ceramic foam filters have an extended operational life, reducing the frequency of maintenance and replacement.

-

Improved Metal Quality: The elimination of impurities from the molten metal significantly improves the mechanical properties and surface finish of the final product.

Applications in Aluminum Production

-

Primary Filtration: Ceramic foam filters are commonly used in primary aluminum production for the initial purification of molten metal.

-

Casting: These filters ensure that impurities are removed before the aluminum is cast into molds, which prevents defects like porosity in the final casting.

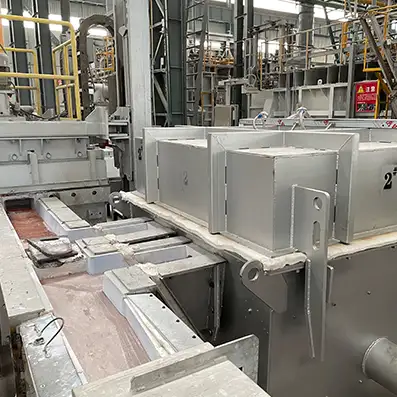

2. Deep Bed Filtration Equipment

Overview

Deep bed filtration equipment is designed to filter aluminum alloys and remove contaminants from molten aluminum using a granular medium. Unlike surface filtration, deep bed filtration relies on the depth of the filtration bed to trap impurities, ensuring a more comprehensive purification process.

Properties and Advantages

-

High Capacity: Deep bed filtration can process large volumes of molten aluminum at high flow rates, making it ideal for large-scale aluminum plants.

-

Effective Removal of Particles: The depth of the filtration medium allows for the removal of fine particles that might otherwise escape through surface filters.

-

Versatility: Deep bed filters can be used to filter various metal alloys, including aluminum, copper, and zinc.

-

Cost-Effective: This filtration method is more cost-efficient for high-volume operations due to its ability to filter large amounts of metal without frequent maintenance.

Applications in Aluminum Production

-

Purification of Recycled Aluminum: Deep bed filters are often used in the recycling of aluminum scrap to remove contaminants such as ash, slag, and dirt.

-

Refining Processes: In aluminum refineries, deep bed filters help purify the metal before it undergoes further processing, ensuring high-quality output.

3. Tubular/Cartridge Filter Equipment

Overview

Tubular and cartridge filter systems offer another method of purification, utilizing cylindrical or tubular filters to remove impurities from molten aluminum. These filters are typically made from materials like stainless steel, which can withstand high temperatures and the corrosive nature of molten metals.

Properties and Advantages

-

Compact Design: Tubular and cartridge filters have a compact structure, making them suitable for smaller setups and tight spaces within the aluminum plant.

-

High Efficiency: These filters provide high filtration efficiency, effectively removing solid particles from the molten metal.

-

Customization: Tubular filters can be customized to meet specific filtration needs, such as different pore sizes or material compositions.

-

Ease of Maintenance: Cartridge filters are designed for easy replacement, reducing downtime and maintenance costs.

Applications in Aluminum Production

-

Secondary Filtration: Tubular and cartridge filters are ideal for secondary filtration processes, where fine impurities must be removed after primary filtration.

-

Specialized Filtration Needs: These filters are used when specific contaminants need to be removed, such as fine oxides or gas bubbles trapped in the aluminum.

4. Importance of Filtration Systems in Aluminum Production

Enhancing Metal Quality

The primary goal of filtration systems in aluminum production is to remove impurities from the molten metal. These impurities, if left unchecked, can negatively impact the mechanical properties, surface finish, and overall quality of the aluminum products. High-quality filtration ensures that the aluminum produced is free from defects such as porosity, cracks, and inclusions.

Reducing Operational Costs

By improving the purity of molten aluminum, filtration systems reduce the likelihood of defects that require costly rework or scrap. Additionally, efficient filtration systems reduce the need for chemical additives or other expensive purification methods, leading to overall cost savings in the production process.

Environmental Benefits

Effective filtration also contributes to environmental sustainability. By reducing the need for additional chemicals and processes, these systems help minimize waste and energy consumption in aluminum production.

5. Technological Innovations and Advancements

The filtration technology used in the Filter Purification Series is continually evolving. New innovations are focused on improving the efficiency and longevity of filtration systems, as well as enhancing their ability to handle complex contaminants. Recent advancements include:

-

Nanotechnology: The development of nanofilters that can remove even smaller particles with higher precision.

-

Self-Cleaning Filters: Filters that automatically remove collected impurities, reducing the need for manual maintenance and increasing operational efficiency.

-

Smart Filtration Systems: Integration of sensors and monitoring systems that track the filter’s performance in real-time, providing valuable data to optimize operations.

6. Maintenance and Care of Filtration Systems

Proper maintenance is critical to ensure the longevity and efficiency of filtration systems in aluminum plants. Regular inspections, cleaning, and timely replacement of filter elements are essential to avoid operational disruptions. Many manufacturers now offer maintenance services to help keep these systems running at peak performance.

FAQs

-

What is the purpose of a Ceramic Foam Filter in aluminum production?

Ceramic foam filters are used to remove impurities from molten aluminum, improving the quality of the final product. -

How does Deep Bed Filtration differ from surface filtration?

Deep bed filtration uses a granular medium to filter molten aluminum, trapping impurities throughout the depth of the medium, while surface filtration works by removing particles from the surface. -

Can Tubular/Cartridge filters be used for other metals?

Yes, tubular and cartridge filters are versatile and can be used for filtering various metal alloys, including copper and zinc. -

What is the main advantage of using Ceramic Foam Filters?

Their high temperature resistance and ability to remove fine impurities make them ideal for molten aluminum filtration. -

How often do filtration systems need to be replaced?

The lifespan of a filtration system depends on the specific technology used and the volume of metal processed. Ceramic foam filters, for example, have a long lifespan and need replacing less frequently than other systems. -

Are there environmental benefits to using filtration systems in aluminum production?

Yes, effective filtration reduces waste and energy consumption, contributing to more sustainable aluminum production. -

How does Deep Bed Filtration enhance aluminum quality?

It removes fine particles and contaminants that surface filters may miss, ensuring higher metal purity. -

What maintenance is required for Tubular/Cartridge Filters?

Regular cleaning and periodic replacement of filter elements are required to maintain filtration efficiency. -

What innovations are being introduced in filtration technology?

Innovations include nanotechnology for finer filtration and self-cleaning filters that reduce maintenance efforts. -

Can filtration systems improve the efficiency of aluminum recycling?

Yes, by removing contaminants from recycled aluminum, filtration systems improve the quality of the metal and make the recycling process more efficient.

Conclusion

The Filter Purification Series—comprising Ceramic Foam Filters, Deep Bed Filtration Equipment, and Tubular/Cartridge Filter Equipment—is essential for maintaining the high standards of purity in aluminum production. These systems not only enhance the quality of the final product but also contribute to more cost-effective and sustainable aluminum manufacturing. As aluminum production technology continues to evolve, filtration systems will play a pivotal role in meeting the industry’s growing demand for high-quality, defect-free metal. The adoption of innovative filtration technologies ensures that aluminum smelters remain competitive while minimizing their environmental impact.