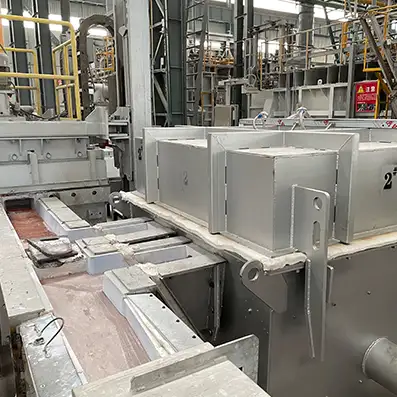

Deep bed filtration equipment installed in an aluminum casting line captures sub-micron and micron-scale inclusions inside a thick porous bed, stabilizes flow into molds, and significantly reduces surface defects and internal discontinuities. When ADtech deep bed systems are paired with appropriate ceramic media and correct preheating, foundries achieve measurable improvements in first-pass yield, reduced machining scrap, and consistent metallurgical quality while lowering lifetime filtration cost compared with many thin-bed or surface-only filters.

Product overview and intended use

ADtech deep bed filtration equipment is engineered for aluminum foundries that require rigorous particle removal and flow conditioning before mold filling. The system uses a multi-layer porous bed made from engineered ceramic or sintered media that traps inclusions within the depth of the filter rather than only on the surface. This deep capture mechanism gives superior removal of fine dross, oxide films, ceramic dust and tramp particles that cause blemishes and weak points in castings. The equipment is suitable for gravity pour, low-pressure and some semi-continuous casting scenarios where controlled head loss and long filter life are priorities.

How deep bed filtration works

Deep bed capture principles

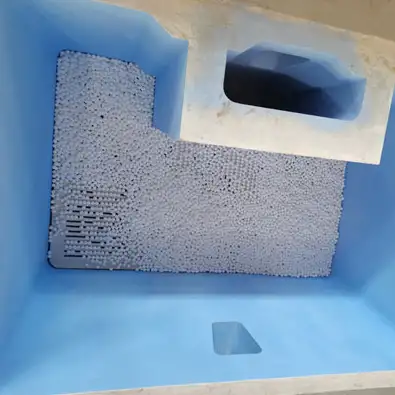

Molten metal flows through a three-dimensional network of pores. Particle retention occurs via interception, inertial impaction, diffusion to strut surfaces, and multipoint adhesion. Over time particles accumulate within the bed, forming internal clog layers that increase capture efficiency without catastrophic flow blockage.

Flow conditioning effect

The bed converts chaotic metal motion into a more uniform, laminar flow. That reduces splashing and gas entrainment and lowers the incidence of flow-related porosity. Properly sized beds also reduce turbulence at gating points, improving mold fill and reducing rework.

| Feature | Ceramic Foam Filter (CFF) | Deep Bed Filtration (DBF) |

| Inclusion Removal Size | > 20 – 40 μm | < 5 – 10 μm (Ultra Fine) |

| Filtration Efficiency | 60% – 80% | 95% – 99%+ |

| Metal Quality Grade | Common / Standard | Aerospace / Foil / Litho |

| Maintenance Cycle | Change per cast | Continuous (Months/Years) |

ADtech product differentiators

-

High-silicon compatible bed supports for chemical stability under aluminum melts.

-

Layered media options – coarse-to-fine gradation to balance permeability and capture.

-

Rapid preheat jackets and controlled heating zones to avoid thermal shock.

-

Modular cassettes for fast changeover and reduced downtime.

-

Engineered nozzle and manifold designs to minimize localized erosion.

-

Data-ready instrumentation for head loss logging and predictive replacement.

Typical configurations and media options

Table 1: Media layering examples

| Layer | Typical composition | Purpose |

|---|---|---|

| Top coarse layer | Sintered alumina or coarse foam (8-15 PPI) | Capture large dross and distribute flow evenly |

| Middle transition layer | Medium PPI foam or sintered granules (15-30 PPI) | Trap intermediate-size particles and prevent channeling |

| Fine polishing layer | High PPI foam or bonded ceramic fleece (30-60 PPI) | Capture sub-micron inclusions and produce laminar outlet |

Table 2: Common bed materials and properties

| Material | Thermal rating | Typical application | Advantage |

|---|---|---|---|

| High-purity alumina | 900-1200°C | General aluminum casting | Cost-effective, good chemical stability |

| SiC-reinforced alumina | 1000-1200°C | Abrasive melts, heavy cycling | Improved toughness and thermal shock resistance |

| Zirconia-enriched | >1100°C | Specialty or harsh conditions | Highest chemical stability, premium cost |

| Sintered ceramic fleece | 850-1100°C | Final polishing | Excellent fine particle capture |

Performance metrics and target outcomes

Key performance indicators to specify and monitor:

-

Inclusion reduction rate (count and area) measured by metallography.

-

Reduced Pressure Test improvement (RPT index reduction).

-

Head loss at design flow and allowable pour height.

-

Consumable life in working hours or pour tonnes.

-

First-pass yield increase and scrap reduction percentage.

Sizing and selection guide

Select bed area and thickness based on pour mass, pour height, gating design and acceptable head loss. Use a coarse rule:

-

Small batches (≤ 200 kg per pour): compact bed, thicker polishing layer.

-

Medium production (200–1000 kg per pour): layered bed with larger surface area.

-

High throughput or continuous feeds: large-area beds with staged cartridge exchange and automated feeding.

Table 3: Sizing starting points

| Production class | Bed area (mm²) | Typical thickness (mm) | Notes |

|---|---|---|---|

| Small batch | 200 x 200 | 25–50 | Use higher PPI top layer for fine finishes |

| Medium volume | 300 x 300 to 400 x 400 | 50–75 | Balance flow and filtration life |

| High throughput | 500 x 500+ or parallel banks | 75–100 | Consider multiple parallel beds for low head loss |

Installation and commissioning checklist

-

Confirm proper mount and alignment with ladle or transfer runner.

-

Preheat bed and housing gradually to melt or specified preheat temperature to eliminate moisture.

-

Verify sealing surfaces and gaskets to prevent bypass.

-

Install instrumentation – differential pressure transducer, thermocouples, pour counters.

-

Conduct baseline RPT and inclusion analysis before first production pour.

-

Establish recipe: pour height, pour rate, and bed change thresholds.

Operation best practices

-

Keep a controlled preheat program and warm the bed assembly prior to pouring.

-

Record head loss after each pour batch; set alarms for threshold increases.

-

Perform regular skimming upstream to reduce load on the bed.

-

If using flux, time flux application and skimming to minimize flux deposition in the upper layers.

-

Rotate or stage beds if continuous operation is required to allow cooling and inspection while other beds remain in service.

Maintenance, wear and expected service life

Deep beds typically outlast thin filters because capture distributes across depth, not surface-only loading. Expected life depends on contamination load; typical servicing cadence:

-

Visual check after each shift.

-

Differential pressure and pour time trend review weekly.

-

Layer replacement or cassette swap monthly to quarterly depending on throughput.

-

Full housing inspection and refractory check each maintenance shutdown.

Table 4: Maintenance schedule

| Interval | Task |

|---|---|

| Daily | Visual inspection, confirm preheat status |

| Weekly | Log review for head loss, check seals |

| Monthly | Swap expendable layers, inspect nozzle wear |

| Quarterly | Full disassembly and refractory inspection |

Safety and environmental considerations

-

Preheat in controlled ovens to prevent steam explosions; never pour onto cold or damp media.

-

Manage spent media and trapped dross per local regulation; many contain recoverable metal.

-

Use fume extraction near skimming and filtration stations; flux fumes can be hazardous.

-

Provide oxygen or gas monitors if inert atmospheres are present; inert gases are asphyxiants.

-

Ensure operators wear heat-resistant PPE and follow molten metal handling protocols.

Troubleshooting common issues and remedies

Table 5: Troubleshooting matrix

| Symptom | Root cause | Corrective action |

|---|---|---|

| Sudden pressure spike | Plugging of upper layer | Stop pouring, replace top layer or swap cassette |

| Filter bed cracking | Thermal shock or impact | Verify preheat, inspect handling procedures |

| Persistent surface inclusions | Upstream contamination or bypass | Check seals, inspect upstream skimming and degassing |

| Rapid erosion at outlet | High local flow velocity | Redesign nozzle, add erosion-resistant insert |

| Shorter filter life than expected | Excess flux deposition or abrasive contaminants | Adjust flux practice and upstream cleaning |

Integration with degassing and downstream filtration

Deep bed equipment forms part of a melt cleanliness train. Typical sequence:

-

Degassing (rotary or vacuum) to remove dissolved hydrogen.

-

Deep bed filtration to capture inclusions and stabilize flow.

-

Final polishing filter or precision plate to ensure surface finish for critical parts.

Coordinating these steps maximizes metal quality and extends bed life.

Economic justification and ROI modeling

Value drivers:

-

Reduced scrap and rework.

-

Lower downstream machining and finishing.

-

Reduced customer rejects and warranty claims.

-

Lower lifetime filtration costs due to longer bed life and less frequent change-outs.

Table 6: Example ROI snapshot

| Parameter | Example value |

|---|---|

| Annual throughput | 3,500 tonnes |

| Pre-install defect rate | 1.8% |

| Post-install defect rate | 0.6% |

| Annual metal saved | 42 tonnes |

| Annual savings (metal + machining) | Site dependent; illustrative six-figure USD range |

| Annual consumable cost | Moderate; lower than frequent thin filters |

| Expected payback | 6–24 months depending on baseline defect rate |

Run a short site pilot to capture real data for precise payback forecasts.

Product specifications example

-

Housing material: steel shell with high-silicon refractory lining.

-

Media: modular layered cartridges in alumina, SiC, or zirconia options.

-

Heating: electric jacket plus insulated cover; optional induction preheat.

-

Instrumentation: differential pressure sensor, thermocouples, digital HMI for logging.

-

Changeover: manual clamp or hydraulic cassette system for fast replacement.

-

Throughput range: custom from small ladles to multi-tonne continuous systems.

Case studies

A mid-volume plant switched to ADtech deep bed modules and integrated degassing upstream. Result: 45% reduction in surface defect rejections over 6 months and a 30% reduction in total filtration cost per tonne.

Deep Bed Filtration (DBF): Technical FAQ

1. What is the main advantage of a deep bed filter compared with thin surface filters?

2. How should I preheat deep bed media?

3. Can deep bed units be used for continuous casting lines?

4. What instruments help decide when to change a bed?

5. Do deep beds affect pour height limits?

6. Are deep bed media recyclable?

7. How do deep beds interact with fluxing practice?

8. Which bed material should be chosen for heavy cycling?

9. How long does a deep bed last under typical workloads?

10. What documentation should a supplier provide?

Troubleshooting quick reference

-

Rising head loss: inspect for clogging and replace upper layers; check upstream skimming.

-

Cracks or fractures in media: review preheat and handling steps for thermal shock risk.

-

Persistent inclusions: analyze gating for bypass and confirm no edge leakage.

-

High nozzle erosion: add erosion inserts and review flow velocity.