Custom-engineered precast refractory shapes outperform traditional field-cast linings by offering superior density, consistent physical properties, and significantly reduced installation time. Industrial facilities switching to ADtech precast components experience an average of 40% less downtime and a 25% extension in lining service life compared to conventional monolithic installations. This efficiency stems from controlled manufacturing environments that eliminate the variables of on-site mixing, curing, and firing. By shifting the critical heat-treatment phase to our specialized facility, we deliver a product that is ready for immediate high-temperature service upon delivery.

The Engineering Behind High-Performance Precast Shapes

Creating a durable refractory shape begins long before the casting process. It starts with precise engineering. Unlike standard brickwork, precast shapes function like complex mechanical components. They must withstand thermal shock, mechanical abrasion, and chemical attack simultaneously.

Thermal Stress Analysis and Geometry

The geometry of a shape dictates how it handles heat. Sharp corners and uneven cross-sections create stress risers. These are points where cracks initiate during rapid temperature changes. ADtech engineers utilize Finite Element Analysis (FEA) to simulate thermal loads. We prioritize rounded edges and uniform wall thickness. When a design requires a transition from thick to thin sections, we implement gradual tapers. This approach allows heat to dissipate evenly through the block.

Anchoring System Integration

Anchors are the backbone of any large precast shape. Incorrect anchor placement leads to catastrophic failure where the concrete breaks away from the metallic or ceramic support.

We design anchoring systems based on three factors:

-

Weight distribution: Heavier blocks require reinforced alloy hooks.

-

Thermal expansion allowance: Metal expands more than refractory concrete. We coat anchors with bitumastic paint or plastic caps to create a buffer zone.

-

Material compatibility: The metallurgy of the anchor must match the maximum service temperature of the furnace.

Technical Note: For operating temperatures above 1100°C (2012°F), we recommend ceramic anchors or high-grade stainless steel (310S or Inconel) to prevent oxidation and loss of strength.

Material Selection: Formulating for Longevity

The performance of a precast shape relies heavily on the raw materials. We do not use generic castables. ADtech formulates specific mixes based on the operational environment of the client.

Aggregate and Matrix Optimization

The “skeleton” of the shape is the aggregate. We use fused alumina, tabular alumina, or silicon carbide depending on the need for wear resistance or thermal conductivity. The “matrix” is the fine powder and binder that holds the skeleton together.

We carefully control the Particle Size Distribution (PSD). By mixing large, medium, and fine particles in exact ratios, we achieve maximum packing density. This reduces porosity. Lower porosity prevents molten slag or corrosive gases from penetrating the block.

Advanced Bonding Mechanisms

Traditional cement bonds can weaken at intermediate temperatures. We utilize advanced bonding technologies:

-

Low Cement Castables (LCC): Contains less calcium aluminate cement. This results in higher strength at high temperatures.

-

Phosphate Bonding: Ideal for applications requiring rapid repairs and resistance to acid slag.

-

Sol-Gel Bonding: A colloidal silica bond that speeds up drying and improves resistance to alkali attack.

Table 1: Common Material Properties for ADtech Precast Shapes

| Material Type | Alumina Content (%) | Bulk Density (g/cm³) | Max Service Temp (°C) | Primary Application |

| AD-HighAl 60 | 60% | 2.55 | 1600 | General furnace linings, walls |

| AD-Tabular 90 | 90% | 2.95 | 1800 | Burner pipes, delta sections |

| AD-SiC 80 | 80% (SiC) | 2.65 | 1500 | High abrasion areas, cement kiln risers |

| AD-Zircon 30 | 30% (ZrO2) | 3.60 | 2000 | Glass tank feeder parts |

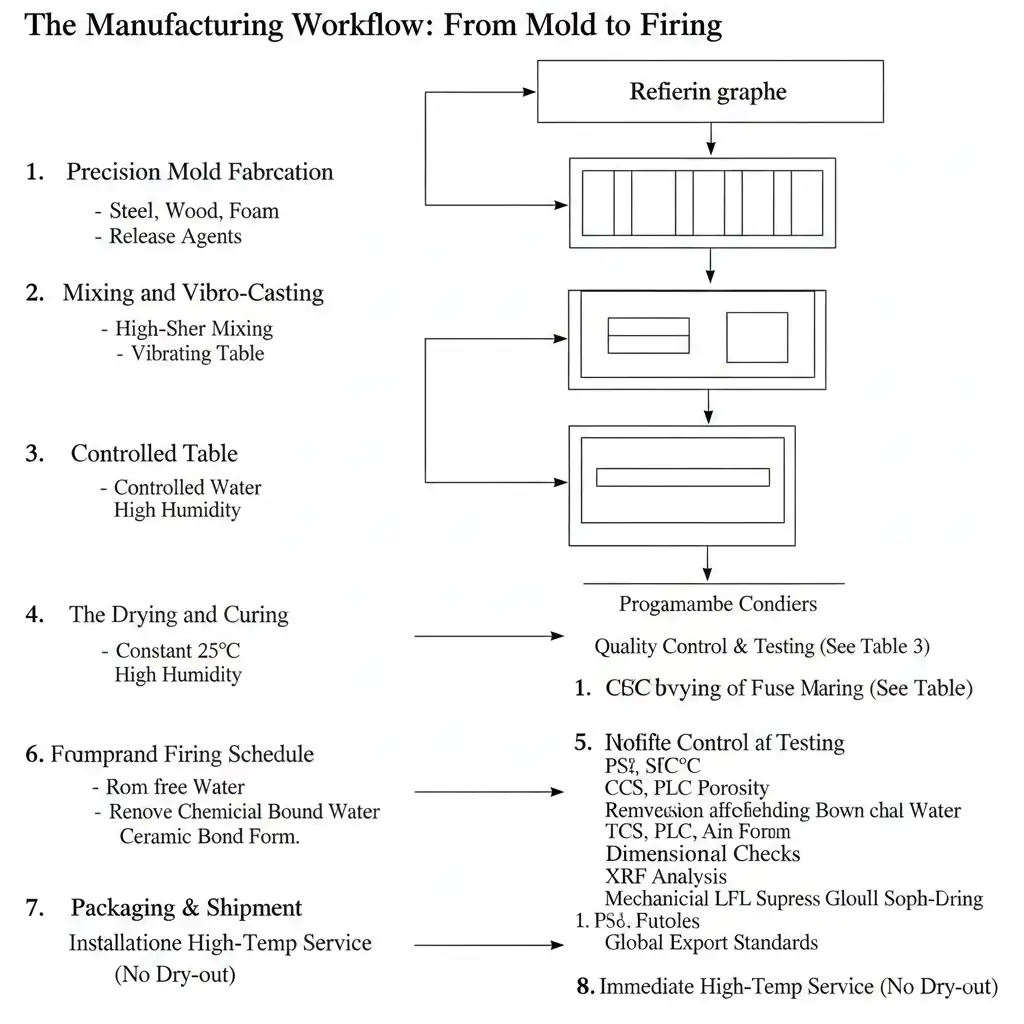

The Manufacturing Workflow: From Mold to Firing

Quality consistency differentiates a backyard operation from a professional manufacturer like ADtech. We adhere to a strict protocol for every shape produced.

1. Precision Mold Fabrication

The mold determines the dimensional accuracy. We use steel, wood, or high-density foam molds. For high-volume production, steel molds are preferred because they maintain tolerance over hundreds of cycles. The mold surface is treated with release agents to ensure a smooth finish on the final product.

2. Mixing and Vibro-Casting

Water addition is the most critical variable. Too much water creates pores; too little results in honeycombing. We use high-shear paddle mixers to activate the additives with minimal water.

During casting, the mold sits on a vibrating table. We adjust the frequency to match the thixotropic properties of the castable. This forces air bubbles out and ensures the material fills every crevice of the mold.

3. Controlled Curing Conditions

Curing allows the binder to hydrate and form strong chemical links. This process is sensitive to temperature and humidity. ADtech curing rooms maintain a constant 25°C (77°F) with high humidity levels. We monitor the exotherm (heat generated by the chemical reaction) to prevent cracks from forming while the shape is still green (unfired).

4. The Drying and Firing Schedule

This is where precast shapes gain their primary advantage. Removing water from refractory concrete is dangerous if rushed. The water turns to steam and can explode the block.

We use programmable gas-fired kilns. The temperature ramps up slowly:

-

Ambient to 110°C: Removal of free water.

-

110°C to 350°C: Removal of chemically combined water.

-

350°C to 800°C: Ceramic bond formation.

Why Choose Precast Over Brick or Monolithic?

Many plant managers hesitate to switch from standard bricks or field-poured castables. However, the operational data supports the switch to precast.

Elimination of Installation Variables

Field installation is chaotic. Dust, varying ambient temperatures, and human error during mixing affect the final quality. Precast shapes are made in a factory. The quality is verified before the product ever reaches your site.

Speed of Installation

Laying thousands of bricks takes weeks. Installing large precast blocks takes days. Since the precast shapes are already fired, you do not need to perform a long “dry-out” cycle after installation. You can ramp the furnace up to operating temperature almost immediately.

Table 2: Comparison of Refractory Lining Methods

| Feature | Standard Bricking | Field-Poured Monolithic | ADtech Precast Shapes |

| Installation Speed | Slow (Manual labor intensive) | Medium (Requires formwork) | Fast (Crane/lift assist) |

| Joints (Weak Points) | Many joints | Few joints | Engineered interlocking joints |

| Drying Required | No | Yes (3-7 days onsite) | No (Pre-fired) |

| Material Density | High | Variable | Consistently High |

| Labor Cost | High | Medium | Low |

Critical Applications in Heavy Industry

ADtech precast solutions serve sectors where heat is a tool and a threat.

Cement and Lime Industry

The nose ring and burner pipe in a rotary kiln suffer from extreme thermal shock and abrasion from clinker. Precast blocks here outlast steel because they do not deform under heat. We also supply shapes for the cooler bull nose and tertiary air duct dampers.

Steel and Aluminum

In steel ladles, precast bottom impact pads withstand the force of molten metal being tapped. For aluminum furnaces, our non-wetting formulations prevent corundum growth on the ramps and hearths.

Petrochemical Heaters

Burner tiles in reformers define the flame shape. If these degrade, flame impingement can damage the process tubes. Our high-precision burner tiles ensure correct aerodynamics for the flame.

Case Study: Cement Plant Optimization in Vietnam

Time: March 2023

Location: Ha Nam Province, Vietnam

Client: A large-scale Portland cement manufacturer (Name withheld for privacy)

The Challenge:

The client was experiencing repeated failures in their kiln burner pipe. The original lining was a field-applied gunning mix. Due to the intense vibration and thermal cycling (1400°C), the lining would crack and fall off every 3 to 4 months. This forced unscheduled shutdowns, costing the plant approximately $150,000 per day in lost production.

The ADtech Solution:

We proposed a conversion to a precast design.

-

Design: We engineered a segmented hexagonal system using AD-Tabular 90 (High purity alumina).

-

Anchoring: We utilized V-anchors made from grade 310 stainless steel, pre-welded to a steel sleeve that slid over the burner pipe.

-

Manufacturing: The shapes were cast, cured, and fired at our facility to 600°C to ensure all water was removed.

The Result:

Installation took 12 hours instead of the usual 48 hours for gunning and drying. The kiln fired up immediately.

-

Lifespan: The new burner pipe lining has been in operation for 14 months and is still performing well.

-

Savings: The client avoided three shutdown cycles, saving an estimated $1.8 million in production losses over the year.

Quality Control and Testing Standards

We maintain trust through transparency. Every batch of ADtech precast shapes undergoes rigorous testing in our laboratory. We follow ASTM and ISO testing protocols.

Physical Property Verification

We cast test cubes alongside the main production run. These cubes are tested for:

-

Cold Crushing Strength (CCS): Ensuring the block can handle structural loads.

-

Permanent Linear Change (PLC): Verifying the shape will not shrink or expand excessively at high heat.

-

Porosity: Confirmed via the Archimedes method.

Dimensional Tolerance Check

A precast shape must fit perfectly. If the tolerances are loose, gaps will form. These gaps allow heat to bypass the lining and damage the steel shell. We use laser measurement tools to ensure all dimensions are within ±2mm (or tighter upon request).

Table 3: ADtech Quality Assurance Metrics

| Test Parameter | Standard Used | Frequency | Acceptance Criteria |

| Chemical Composition | X-Ray Fluorescence (XRF) | Every Batch | ±1% of spec |

| Bulk Density | ASTM C134 | Every Batch | > Spec Minimum |

| Cold Crushing Strength | ASTM C133 | Every Batch | > Spec Minimum |

| Internal Flaws | Ultrasonic Testing | Random Spot Check | No internal voids >3mm |

Troubleshooting Common Refractory Issues

Even with the best materials, issues can arise if the operating conditions change. Here is how we diagnose problems.

Thermal Spalling

If a shape cracks in layers parallel to the hot face, it is thermal spalling. This happens when temperature changes occur too fast.

-

Fix: We adjust the mix to include organic fibers. These fibers burn out, leaving tiny channels that allow steam to escape and provide flexibility.

Structural Spalling

This occurs when the slag penetrates the brick and alters its chemistry. The penetrated layer expands differently than the rest of the block and snaps off.

-

Fix: We increase the density of the mix or add non-wetting agents (like Barium Sulfate or specific salts) to repel the slag.

Anchor Failure

If the concrete is intact but falls off the wall, the anchor failed.

-

Fix: We analyze the failed anchor. If it melted, we upgrade the alloy. If it snapped, we check for proper expansion gaps.

Future Trends in Refractory Technology

The industry is moving toward “Smart Refractories.” ADtech is currently researching the integration of wear sensors within precast blocks. These sensors will send data to the control room, alerting operators when the lining thickness reaches a critical level. This predictive maintenance model will eliminate unexpected failures entirely.

Furthermore, we are developing “Nano-Bonded” castables. By using nanotechnology in the matrix, we can reduce the pore size to the nanometer range. This will make the shapes virtually impervious to gas and slag penetration.

Frequently Asked Questions (FAQs)

1. What is the lead time for custom precast shapes?

Typically, the lead time is 3 to 5 weeks. This includes mold design, fabrication, casting, curing, and firing. Rush orders can be accommodated depending on mold complexity.

2. Can I install precast shapes myself?

Yes. Since the shapes are pre-fired, installation is mechanical (welding anchors or bolting). However, we recommend having an ADtech supervisor present to ensure proper joint sealing.

3. What mortar should I use between precast blocks?

We often recommend no mortar (dry joints) for many applications to allow for expansion. If sealing is needed, use a ceramic fiber blanket or a specific phos-bonded mortar that matches the chemistry of the block.

4. How do you transport large precast shapes?

We use heavy-duty wooden crates with foam padding. Critical surfaces are protected. We ship globally and ensure packaging meets international export standards.

5. What is the maximum weight you can cast?

We have cast single blocks weighing up to 5 metric tons. For larger assemblies, we design segmented systems to facilitate transport and installation.

6. Do precast shapes cost more than bricks?

The initial material cost is often higher than standard bricks. However, when you factor in the elimination of formwork, reduced installation labor, and longer service life, the total cost of ownership is usually lower.

7. Can you replicate an existing shape from a drawing?

Yes. We can work from 2D PDF drawings, 3D CAD files, or even reverse-engineer a physical sample if the drawings are lost.

8. What happens if a shape breaks during operation?

Precast linings are modular. You only need to remove and replace the damaged block, not the entire wall. We recommend keeping a few spare shapes in stock for emergency repairs.

9. Are your shapes compatible with hydrogen burners?

Yes. Hydrogen combustion produces higher moisture content. We have specific low-silica formulations resistant to the reducing atmosphere and high water vapor pressure of hydrogen firing.

10. How do you prevent the shapes from sticking to the mold?

We apply specialized wax-based or oil-based release agents. For complex geometries, we use flexible polyurethane mold liners to allow for easy demolding without damaging edges.

Ready to Upgrade Your Refractory Performance?

If your current lining is failing too often or if you need to reduce your next shutdown window, ADtech is ready to assist. We do not just sell products; we sell reliability.