For highest accuracy in molten aluminum temperature measurement, combine immersion Type S thermocouples for direct-contact peak readings with multi-wavelength optical pyrometers for continuous non-contact monitoring, and maintain frequent calibration using traceable standards to minimize process variation and scrap.

Why temperature control matters in aluminum melting and casting

Temperature controls melt quality, fluidity, dissolved gas content, and final mechanical properties. Poor temperature control raises scrap rate, changes alloy composition through excessive oxidation, and increases energy cost per unit. Reliable measurement provides repeatable process setpoints, aids in degassing timing, and reduces rework.

Core measurement strategies

There are two mainstream approaches used in industrial aluminum production: direct-contact immersion sensors and non-contact optical sensors. Each method presents tradeoffs in speed, longevity, contamination risk, and integration complexity. Most foundries combine both types to gain redundancy and continuous feedback.

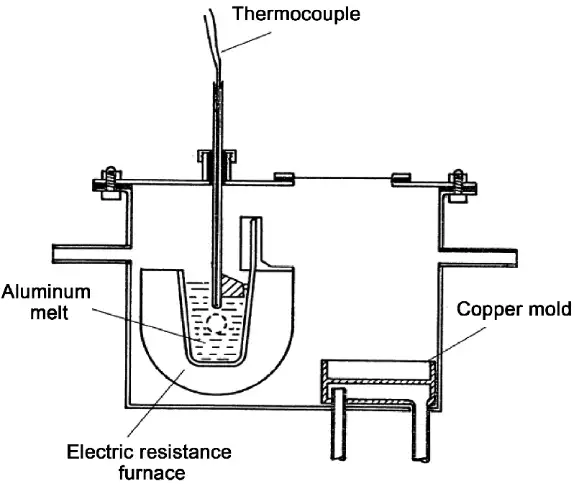

Immersion thermocouples — direct reading with protection

Why immersion sensors remain common

Immersion probes provide the most direct link to metal temperature. They measure within the melt, capturing bulk temperature that optical systems can miss in the presence of slag or surface film. Proper probe choice reduces contamination risk and gives repeatable peak readings that control loops can use for process decisions.

Immersion sensors are offered in fixed and disposable designs. Fixed probes use heavy-duty sheath materials and protective tubes. Disposable probes provide low-cost, single-use tips for high-wear operations where probe tip failure is expected.

Thermocouple types and practical ranges

| Thermocouple type | Typical max service | Key trait | Common foundry use |

|---|---|---|---|

| Type S (Pt10%Rh/Pt) | ~1600°C (traceable high-temp) | Stable at high temp, good drift resistance | Critical control points, high-accuracy checks |

| Type K (Chromel/Alumel) | ~1370°C | Low cost, rapid response | General-purpose monitoring |

| Type B (Pt30%Rh/Pt6%Rh) | ~1700°C | Designed for extreme temperature stability | High-temp melt applications |

Heavy-duty thermocouples built for molten metal often use sheath materials selected for thermal shock and chemical resistance. For aluminum, stainless alloys or ceramic-protected elements are common. Protection tubes and ceramic sleeves increase service life and reduce wetting by liquid metal.

Industry suppliers offer immersion assemblies tailored for tundish, ladle, crucible, and pouring applications. The goal is to achieve fast response while preventing wire wetting and probe burnout. Disposable tips are used where tip erosion or repeated mechanical stress leads to frequent failures. Practical system accuracies depend on probe type, meter, and installation method; calibrated Type S systems deliver the tightest uncertainty for molten metal control.

Probe installation and handling

- Insert probe to a consistent depth to ensure comparability between readings.

- Use a fixed mount or repeatable holder to avoid movement during measurement.

- Protect junction and cable from radiant heat using shields or extended handles.

- Replace expendable tips before corrosion reaches the thermocouple junction.

Optical pyrometers and infrared systems

Principle and spectral selection

Optical temperature sensors compute temperature from emitted radiation. The measured signal depends on wavelength, sensor field of view, and surface emissivity. Molten aluminum does not behave like an ideal emitter. That complicates single-wavelength readings, especially when surface conditions change due to oxide film, slag, or fumes. For that reason, multi-wavelength instruments or systems with built-in emissivity compensation yield more consistent results in industrial service.

Single-wavelength units — low cost, conditional accuracy

Single-band pyrometers work well if surface emissivity is known and stable. They offer fast response, zero-contact measurement, and no risk of contamination. However, readings shift when emissivity changes from surface oxide, splashing, or foaming.

Multi-wavelength pyrometers

Multi-wavelength sensors measure radiance at two or more wavelengths and apply algorithms to compensate for non-greybody behavior. In molten aluminum, that ability produces more repeatable readings in environments with changing surface conditions and strong reflections. Multi-wavelength instruments are the preferred option where continuous monitoring must feed control loops.

Practical limits for optical systems

- Line of sight must remain clear; fumes, smoke, or physical obstructions reduce reliability.

- Rapidly moving melts may require short integration times to avoid measurement lag.

- Calibration uses blackbody references or traceable standards to maintain accuracy.

Comparing immersion and optical approaches

| Attribute | Immersion thermocouple | Optical pyrometer |

|---|---|---|

| Contact with melt | Yes | No |

| Response time | Moderate to fast | Very fast |

| Contamination risk | Higher (possible junction wetting) | None |

| Dependence on surface condition | Low | High for single-band sensors |

| Maintenance | Probe replacement, protection tube wear | Lens cleaning, recalibration |

Accuracy, calibration, traceability

Good measurement requires regular calibration and traceable reference points. Traceable calibration to national standards reduces process uncertainty and supports quality documentation during audits. Calibration frequency depends on sensor wear rate and control limits for the process. Typical foundry practice for molten metal temperature systems includes routine comparison against a calibrated reference probe or blackbody standard prior to critical pours.

Published manufacturer data and application notes highlight the difference between sensor types plus recommended calibration practices. For molten aluminum, supplier literature suggests careful spectral selection for pyrometers and specifies thermocouple types and calibration methods that meet industrial accuracy needs.

System accuracy numbers you can expect

Manufacturers publish typical uncertainties for common product families. For example, countertop immersion systems with commercial instruments often quote system uncertainties near ±5°F to ±20°F depending on thermocouple type and meter quality. Field systems built from high-quality Type S assemblies plus precision instrumentation can hold better tolerances. For repeatable industrial control, achieving system uncertainty under ±10°F is a practical target using Type S probes and proper calibration.

Common failure modes and root causes

| Failure mode | Root cause | Remedy |

|---|---|---|

| Drift in reading | Thermocouple aging, contamination | Replace tip, recalibrate sensor |

| Intermittent readings | Poor junction contact, cable damage | Check connections, replace wiring |

| Optical noise | Obstructed view, fumes | Install purge air, reposition sensor |

| Incorrect absolute value | Wrong emissivity setting, wrong probe type | Adjust emissivity, swap to correct probe |

Installation checklist for reliable operation

- Secure sensor mounting with vibration isolation.

- Route cables away from radiative heat. Use heat shields when needed.

- Establish a calibration schedule and keep records.

- Provide lens purge or air knife for optical sensors to keep field of view clear.

- Keep spare expendable tips and protection tubes in inventory.

- Document measurement depth and sampling point for repeatability.

Integration with process control systems

Measurement is useful only when it feeds control logic. Typical integration uses thermocouple inputs on PLCs, data acquisition systems, or dedicated melt-temperature controllers. Optical pyrometers often include analog current output 4–20 mA, RS-485, or Ethernet connectivity. Ensure signal conditioning and cold-junction compensation are correct. In mixed-sensor installations, implement sensor fusion logic to reconcile thermocouple spikes with optical averages.

Selecting the right sensor for your application

Key decision factors include melt volume, duty cycle, target accuracy, and budget. Small melting furnaces with frequent metal handling may favor disposable dipstick-style probes to reduce unplanned downtime. Larger operations with continuous casting lines often use fixed, robust immersion probes plus a through-line optical sensor for redundancy.

| Use case | Recommended sensor | Rationale |

|---|---|---|

| Batch melting, low throughput | Handheld immersion probe | Low capital, good peak reading |

| Continuous casting line | Fixed immersion probe + multi-wavelength pyrometer | Redundancy, continuous feedback |

| High erosion environment | Disposable tip thermocouples | Lower replacement cost, predictable maintenance |

Practical examples

Many foundries combine a dipstick thermocouple for occasional verification with a permanently mounted pyrometer feeding the control loop. For molten aluminum, Type S thermocouples have strong adoption because of their stability at high temperatures and reduced drift in service. Industry application notes and supplier literature emphasize that multi-wavelength pyrometers produce better consistency during casting because they reduce sensitivity to surface-reflective behavior.

Research and emerging methods

Recent technical work blends multi-spectral optical methods with machine learning-based emissivity estimation to improve non-contact accuracy under dynamic surface conditions. Hybrid systems that correlate immersion probe peaks with continuous optical trends provide better process control and early detection of thermal anomalies. Academic studies show that combining k-type armored thermocouples with infrared methods gives a practical balance between cost and performance for many operations.

Maintenance plan template

- Daily: visual inspection of sensors and cables; lens cleaning for optical units.

- Weekly: check mounting hardware, record calibration drift checks.

- Monthly: full signal test against reference probe; inspect protection tubes for wear.

- Quarterly: traceable calibration of at least one reference sensor; update control offsets.

- Yearly: manufacturer calibration or swap to newly calibrated units for critical points.

Common measurement pitfalls and corrective actions

- Incorrect emissivity setting gives biased pyrometer readings: verify emissivity on a known sample before production run.

- Junction wetting on immersion probes gives under-reading due to heat sink effect: use protection tube with ceramic tip to delay wetting.

- Loose connectors produce noisy data: implement torque-controlled connector tightening or lockable housings.

- Ambient heat causing cable damage: route cables with reflective shielding and ventilation.

Three practical tables for quick reference

Table 1 Thermocouple selection quick reference

| Priority | Choose | Why |

|---|---|---|

| Highest accuracy | Type S immersion | Good high-temp stability, low drift |

| Best value | Type K with protection tube | Lower cost, acceptable performance |

| Extreme temp | Type B | Designed for very high temperatures |

Table 2 Pyrometer spectral guidance

| Spectral band | Good fit for | Notes |

|---|---|---|

| Short wave (0.5–1.0 μm) | Bright metals, small spot | Less affected by contamination when properly selected |

| Mid wave (1.0–3.0 μm) | General metal monitoring | Requires emissivity attention |

| Multi-wavelength | Molten aluminum | Compensates for non-greybody effects |

Table 3 Quick troubleshooting matrix

| Symptom | Likely cause | Immediate action |

|---|---|---|

| Sudden temperature jump | Probe contact failure or shorting | Remove probe, inspect tip, compare with backup sensor |

| Slow, stale readings | Probe insulation degradation | Replace protection tube, retest response time |

| Consistent offset | Calibration drift | Run calibration check, adjust offset |

Regulatory traceability and documentation

Traceable calibration certificates build audit trails for quality systems. When product specification or customer contracts require tight tolerances, keep calibration certificates from accredited labs on file. For critical pours, run pre-pour verification protocols and log sensor IDs, calibration dates, and measured offsets.

Cost considerations and ROI

Investment in robust temperature measurement reduces scrap and rework costs. Calculate return on investment by estimating reduced scrap percentage, energy savings from tighter control, and labor savings from fewer manual interventions. Multi-sensor redundancy reduces catastrophic failures that lead to lost production time.

Vendor selection tips

- Choose vendors that offer application engineering support, not just catalog items.

- Request reference installations for similar alloys and throughput rates.

- Verify spare parts availability and lead times for expendable tips or lenses.

- Ask for test data showing performance in molten aluminum with varying surface conditions.

Frequently asked questions

- Q: Which sensor gives the truest instant reading?A: An immersion probe placed in the melt gives the closest reading to bulk temperature. To achieve consistent results, use a properly protected thermocouple and insert it to a repeatable depth.

- Q: Can an infrared thermometer be trusted for melts?A: Handheld infrared tools can give useful readings for rough checks, but they depend on emissivity and may change with surface condition. For production control, choose industrial pyrometers with spectral settings matched to aluminum.

- Q: Which thermocouple type is recommended?A: Type S is recommended when stability and low drift matter. Type K offers lower cost and fast response for many routine tasks.

- Q: How often should sensors be calibrated?A: Calibration frequency depends on usage and criticality. For critical control points, run monthly checks with a reference sensor and perform full calibration quarterly or yearly depending on drift trends.

- Q: Why do optical readings change quickly?A: Optical readings sense surface radiance. Surface films, splashing, fumes, or reflections modify radiance quickly. Multi-wavelength instruments reduce that sensitivity.

- Q: What causes thermocouple wetting?A: Wetting occurs when molten metal adheres to the probe sheath and reaches the junction. Using ceramic sleeves or protective tubes delays wetting and extends probe life.

- Q: Is a disposable probe worth the cost?A: For high-abrasion or splash environments, disposable tips reduce unplanned downtime and can lower total cost when tip life is short.

- Q: Can pyrometers measure through openings or over long distances?A: Pyrometers have finite optics and field-of-view limitations. Long-distance measurements need careful selection of optics, focusing, and perhaps protective windows with purge systems.

- Q: How to set emissivity for molten aluminum?A: Determine emissivity by calibration against a reference probe or blackbody at the operating temperature and surface condition. Maintain a log of emissivity settings tied to production states.

- Q: What redundancy strategy works best?A: Combine an immersion thermocouple for peak verification with a multi-wavelength pyrometer for continuous monitoring. Implement alarm thresholds on agreement between sensors to flag failures.

Final checklist before deployment

- Validate sensor type against process temperature and alloy.

- Confirm pyrometer spectral selection for aluminum’s radiative properties.

- Complete wiring, cold-junction compensation, and signal validation.

- Run calibration against a traceable reference and document results.

- Train operators on reading interpretation and maintenance tasks.

Closing summary

Molten aluminum temperature measurement demands a pragmatic combination of methods to balance accuracy, uptime, and cost. Immersion thermocouples deliver direct measurements for peak values. Optical multi-wavelength pyrometers deliver continuous, contact-free monitoring that resists changing surface radiance. A hybrid installation plus disciplined calibration produces the best production outcomes and lowest total cost of ownership.