Ceramic Fiber Insulation Tape is a critical thermal management component for aluminum foundries, offering continuous temperature resistance up to 2,300°F (1,260°C). Composed of high-purity alumino-silicate fibers, it serves as an essential barrier against thermal shock and heat loss in transfer launders, degassing units, and filtration boxes. For AdTech’s client base—technical engineers and procurement specialists—selecting the correct weave, reinforcement (Inconel/Glass), and density is the deciding factor in preventing molten metal freeze-off and ensuring personnel safety.

1. The Material Science of Alumino-Silicate Thermal Barriers

To understand why ceramic fiber tape dominates the high-temperature insulation market, we must examine its mineralogy. Unlike standard textiles, this material is derived from a blend of Alumina (Al2O3) and Silica (Si2O3). This specific chemical composition creates a refractory fiber that remains stable even when exposed to direct flame or radiant heat from molten aluminum.

In the context of an aluminum cast house, the primary enemy is not just heat, but thermal shock. When a transfer launder is preheated or when molten aluminum (typically at 700°C – 750°C) is introduced, materials with high coefficients of thermal expansion will crack or delaminate. Ceramic fiber tape possesses a near-zero coefficient of thermal expansion, meaning it maintains dimensional stability during rapid temperature, cycling.

The insulation mechanism operates on three levels:

-

Conduction Blocking: The porous structure of the woven fibers traps pockets of stagnant air, which is a poor conductor of heat.

-

Radiation Reflection: The white, crystalline surface reflects infrared radiation, keeping the heat energy contained within the process equipment (e.g., the launder or filter box).

-

Convection inhibition: By tightly wrapping components, the tape prevents the convective movement of hot air away from the metal surface.

2. Technical Specifications & Performance Metrics

For procurement managers and engineers validating data sheets, the following parameters define high-quality ceramic fiber tape suitable for AdTech’s equipment ecosystem.

Key Performance Indicators (KPIs)

-

Continuous Service Temperature: 2,300°F (1,260°C).

-

Melting Point: 3,200°F (1,760°C).

-

Tensile Strength: Dependent on reinforcement (see Section 5), but typically ranges from high-strength for wire-reinforced to moderate for standard weaves.

-

Loss on Ignition (LOI): < 15% (This refers to organic binders burning off during the initial heat cycle).

-

Dielectric Strength: High (unless wire reinforced).

Standard Dimension Table

| Characteristic | Specification Range | Application Context |

| Thickness | 1/16″ (1.6mm) to 1/4″ (6.4mm) | Thicker tapes used for primary insulation; thinner for gaskets. |

| Width | 1″ (25mm) to 6″ (150mm) | Narrow for pipe wrapping; wide for launder joints. |

| Density | 30 – 34 lb/ft³ (480 – 550 kg/m ³) | Higher density equals better durability against abrasion. |

| Weave Type | Plain or Drop Warp | Plain weave offers tighter structure; drop warp allows bolt insertion (ladder tape). |

3. Critical Applications in Aluminum Foundries (AdTech Focus)

AdTech specializes in degassing and filtration. The integration of high-temperature tape is not merely an accessory but a necessity for process stability.

3.1 Sealing Launder Joints

In long launder runs, sections are joined together. These joints are vulnerable to molten aluminum leakage and heat loss. Placing a strip of ceramic fiber tape (often referred to as a “gasket” in this context) between the refractory launder sections creates a compression seal. This prevents aluminum penetration and accommodates the slight expansion of the refractory material.

3.2 Insulation of Degassing Unit Components

The rotor and shaft in a degassing unit operate under extreme stress. While the shaft itself is graphite or ceramic, the upper mechanical connections and gas inlet pipes require insulation to protect seals and bearings from the radiant heat rising from the melt. Ceramic tape provides a flexible, removable shield that withstands the 750°C environment without degrading.

3.3 Protection of Automation Cables & Hydraulics

Modern foundries are automated. Hydraulic lines and sensor cables often run near the casting table. A single splash of molten aluminum can rupture a hydraulic hose, causing a fire. Wrapping these lines in ceramic fiber tape (often with a vermiculite coating for extra splash resistance) provides a sacrificial thermal layer that buys time and prevents catastrophic failure.

3.4 Filter Box Gaskets

When seating a Ceramic Foam Filter (CFF) bowl or the filter box lid, an air-tight seal is required to prevent re-oxidation. Ceramic fiber tape acts as a compressible gasket that ensures the lid sits flush, maintaining the protective atmosphere above the melt.

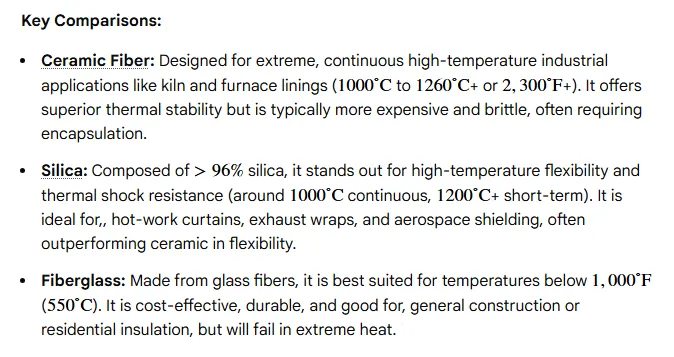

4. Comparative Analysis: Ceramic Fiber vs. Fiberglass vs. Silica

Engineers often confuse these materials. Using fiberglass in an aluminum application is a common failure point.

Comparative Data Table

| Feature | Fiberglass Tape | Ceramic Fiber Tape | Silica Tape |

| Max Temp | 1,000°F (540°C) | 2,300°F (1,260°C) | 1,800°F (982°C) |

| Base Material | Borosilicate Glass | Alumino-Silicate | High Purity Silica (>96%) |

| Aluminum Resistance | Poor (Melts/brittle) | Excellent (Non-wetting) | Good |

| Abrasion Resistance | High | Moderate | Low |

| Cost | Low | Medium | High |

| Primary Foundry Use | Cold face plumbing | Molten metal contact areas | Special high-purity needs |

Algorithm Note: The distinction here is vital. Fiberglass will fail almost instantly if touched by molten aluminum, whereas ceramic fiber tape will generally resist wetting, allowing the aluminum to shed off.

5. Reinforcement Technologies: Wire vs. Fiberglass Filament

Ceramic fibers, by nature, do not possess high tensile strength. To weave them into a tape, a carrier material is required. This carrier dictates the mechanical limits of the tape.

Nickel-Chrome (Inconel) Wire Reinforcement

-

Construction: Stainless steel or Inconel wires are twisted with the ceramic yarn.

-

Purpose: Maintains physical integrity at maximum temperatures (2,000°F+). Even if the ceramic fiber degrades slightly, the wire holds the tape in place.

-

Drawback: The wire makes the tape conductive. It cannot be used for electrical insulation wrapping.

-

AdTech Use Case: Wrapping launder exteriors and high-vibration piping.

Fiberglass Filament Reinforcement

-

Construction: Glass filaments are inserted into the yarn.

-

Purpose: Provides tensile strength during installation (wrapping).

-

Limitation: The glass filament burns out at approx. 1,200°F. However, by that time, the ceramic fiber has typically “set” in place.

-

AdTech Use Case: Gasketing applications where the material is compressed and does not rely on tensile strength after installation.

6. Installation Protocols for Launder Systems & Piping

Improper installation compromises the thermal efficiency (R-value) of the system. Follow these expert protocols.

Step 1: Surface Preparation

Ensure the launder shell or pipe is free of oil and grease. While the tape can handle oil, grease trapped under the tape can carbonize and create hot spots.

Step 2: The 50% Overlap Rule

When wrapping cylindrical objects (pipes, thermocouple protection tubes), spiral the tape with a 50% overlap. This ensures that there is always a double layer of insulation at any given point, eliminating “thermal bridging” where heat escapes through the seams.

Step 3: Tension Management

Apply moderate tension. Ceramic fiber tape is not elastic. Pulling too tight will separate the weave, reducing insulation value. Too loose, and it will slide.

Step 4: Securing the Ends

Do not use standard electrical tape or plastic ties. Secure the ends using:

-

Stainless steel hose clamps.

-

Tie wire (Nichrome or Stainless).

-

High-temperature silicate adhesive (sodium silicate based).

Step 5: Initial Firing (The “Smoke-Off”)

New tape contains organic binders (starches/oils) to facilitate weaving. Upon first exposure to heat (above 400°F), these binders will vaporize, creating smoke. This is normal.

Protocol: Ensure adequate ventilation during the first heat cycle. The smoke usually dissipates within 15-20 minutes. The tape will turn brown, then return to white.

7. Chemical Stability & Molten Metal Resistance

In the aluminum industry, “Flux” (salts used to clean metal) and the aluminum itself are chemically aggressive.

-

Acid/Alkali Resistance: Ceramic fiber tape exhibits excellent resistance to most acids (except hydrofluoric and phosphoric acid) and alkalis.

-

Molten Aluminum Wetting: The material is non-wetting. If molten aluminum splashes onto the tape, it tends to bead up and roll off rather than soaking in and destroying the insulation. This is a critical safety feature for operators working near the AdTech filtration box.

-

Oxidation: The tape is unaffected by oxidation or reduction atmospheres, making it suitable for gas-fired furnace environments.

8. Environmental, Health, & Safety (EHS) Compliance

Navigating the regulations surrounding Refractory Ceramic Fibers (RCF) is mandatory for any modern foundry.

RCF Classification

Ceramic fiber is classified as an RCF. In many jurisdictions (EU, US), there are specific handling requirements due to potential respiratory hazards (similar to, but distinct from, asbestos).

Handling Best Practices

-

PPE: Personnel cutting or installing tape should wear N95 respirators (or equivalent), safety goggles, and gloves.

-

Skin Irritation: The fibers can cause mechanical irritation (itching). Wear long sleeves and loose-fitting clothing. Wash work clothes separately.

-

Disposal: Waste ceramic fiber should be bagged in heavy-duty plastic and labeled according to local hazardous waste regulations.

-

Asbestos-Free: It is crucial to certify that AdTech-supplied materials are 100% asbestos-free, a requirement for compliance in Western markets.

9. Troubleshooting & Maintenance in High-Heat Zones

Even the best insulation degrades. Recognizing failure modes saves downtime.

-

Embrittlement: After long exposure to temps >1000°C, the fibers may devitrify (become crystalline) and brittle. If the tape is undisturbed, it remains effective. If the equipment vibrates, the tape may turn to powder.

-

Solution: Use wire-reinforced tape in high-vibration zones.

-

-

Shrinkage: At extreme temperatures, linear shrinkage can occur (typically <3%).

-

Solution: Account for shrinkage by ensuring sufficient overlap during installation.

-

-

Chemical Attack: If flux sprays constantly hit the tape, it may stiffen.

-

Solution: Use a vermiculite-coated version or cover with a sacrificial high-temp cloth.

-

10. Ceramic Fiber Tape: Technical FAQ

1. What is the maximum temperature rating for Ceramic Fiber Tape?

2. Is this tape waterproof?

3. Does the tape come with adhesive backing?

4. Can this tape withstand direct contact with molten aluminum?

5. How do I cut ceramic fiber tape safely?

6. What is the difference between “Woven” and “Twisted” rope/tape?

7. Why is the tape smoking when I first heat it?

8. Is Ceramic Fiber Tape better than Silica Tape?

9. Can I reuse the tape after removing it?

10. Does this product contain Asbestos?

AdTech’s Manufacturing Edge

For our partners in the aluminum industry, AdTech provides not just a roll of tape, but a thermal assurance. Our Ceramic Fiber Insulation Tape is manufactured with strict quality controls on density and weave consistency, ensuring that when you wrap a launder or seal a filter box, the thermal profile remains constant. By controlling the Alumina-Silicate ratio, we maximize thermal shock resistance, specifically catering to the cyclical heating and cooling common in casting operations.