Hot-Top Casting Series

Products

PRODUCTS

CONTACT US

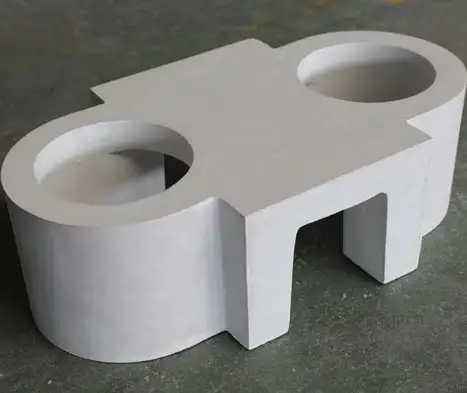

The Hot-Top Casting Series plays a crucial role in the aluminum casting process, ensuring the efficient production of high-quality aluminum products. This product series includes components like the Sprue Bush, Distributing Launder, Hat Plate, Transition Plate, Graphite Ring, and Hot-top Casting Distributing Launder. These elements are specifically designed for use in aluminum foundries to optimize casting processes, enhance material flow, and prevent defects in the final castings.

1. Overview of Hot-Top Casting Series

The Hot-Top Casting Series is an advanced system of components used in aluminum foundries for high-performance casting operations. These parts, including the Sprue Bush, Distributing Launder, Hat Plate, Transition Plate, and Graphite Ring, are designed to work in synergy to improve metal flow, prevent thermal losses, and ensure optimal mold filling. Hot-top casting is a critical part of the aluminum casting process, and these components are essential for maintaining the integrity of the molten aluminum as it travels from the furnace to the mold.

2. Components of the Hot-Top Casting Series

Sprue Bush

The Sprue Bush is a critical component in the aluminum casting process. It serves as a conduit for the molten aluminum, directing it from the furnace or metal reservoir into the casting mold. The Sprue Bush must be made of materials that can withstand high temperatures and the corrosive effects of molten metal. It plays a significant role in maintaining the smooth flow of aluminum, reducing turbulence, and preventing defects such as air pockets or inclusions.

Key Features:

-

High thermal conductivity to ensure even distribution of heat.

-

Designed for high-temperature resistance and durability.

-

Available in various sizes to accommodate different casting molds.

Distributing Launder

The Distributing Launder is used to channel molten aluminum from the furnace to the molds in a controlled manner. It evenly distributes the molten metal to various parts of the mold cavity, ensuring consistent filling. This component helps to maintain the temperature of the aluminum during the casting process and prevents thermal gradients that could result in casting defects.

Key Features:

-

Ensures even distribution of molten metal.

-

Minimizes temperature loss and maintains metal fluidity.

-

Reduces turbulence to prevent air entrapment.

Hat Plate

The Hat Plate is an essential part of the hot-top casting system, acting as a protective cover for the top of the mold. It prevents contaminants from entering the molten aluminum and helps to reduce heat loss during the pouring process. The Hat Plate is typically made of high-strength materials that can withstand the stresses of molten metal exposure while maintaining its shape and functionality.

Key Features:

-

Reduces contamination and heat loss.

-

Provides structural stability to the mold.

-

Made from high-temperature-resistant materials.

Transition Plate

The Transition Plate serves as a bridge between different sections of the casting system, typically connecting the Sprue Bush to the Distributing Launder. It helps to ensure a smooth transition of molten aluminum, reducing turbulence and preventing blockages. The material selection for the Transition Plate is crucial as it must withstand high temperatures and abrasive wear.

Key Features:

-

Ensures smooth transition of molten metal.

-

Prevents turbulence and blockages.

-

Offers high resistance to wear and heat.

Graphite Ring

The Graphite Ring is another vital component in the Hot-Top Casting Series. Graphite is chosen for its excellent thermal conductivity and high resistance to molten aluminum. The Graphite Ring is typically used in applications where precise temperature control and minimal thermal loss are required. It is commonly employed in areas of the casting system that require insulation or where the molten metal needs to be maintained at a specific temperature for an extended period.

Key Features:

-

High thermal conductivity for efficient heat management.

-

Excellent resistance to molten aluminum.

-

Provides insulation and temperature control.

Hot-top Casting Distributing Launder

The Hot-top Casting Distributing Launder is a specialized version of the standard Distributing Launder, designed specifically for the hot-top casting process. It plays a crucial role in distributing molten aluminum evenly throughout the mold. The design of this component helps to reduce the risk of metal oxidation and minimizes the formation of inclusions.

Key Features:

-

Optimized for hot-top casting systems.

-

Ensures uniform metal flow throughout the mold.

-

Prevents oxidation and inclusion formation.

3. Materials Used in the Hot-Top Casting Series

Each component in the Hot-Top Casting Series is made from specialized materials that ensure the durability, thermal efficiency, and strength required in the casting process. These materials are carefully selected to withstand the extreme temperatures and pressures encountered during aluminum casting.

-

Ceramic Materials: Used in components like the Sprue Bush and Distributing Launder for their ability to withstand high temperatures and resist corrosion.

-

Graphite: Commonly used for the Graphite Ring, chosen for its excellent thermal properties and resistance to molten aluminum.

-

High-Strength Steel and Alloys: Used in the Hat Plate and Transition Plate to provide structural integrity and withstand the mechanical stresses of the casting process.

4. Benefits of the Hot-Top Casting Series

Enhanced Casting Quality

By using components that optimize the flow and temperature of molten aluminum, the Hot-Top Casting Series helps to ensure high-quality castings with fewer defects. The even distribution of molten metal reduces the risk of air pockets, inclusions, and temperature gradients, which can all lead to casting imperfections.

Improved Efficiency

The Hot-Top Casting Series is designed to minimize heat loss, reduce turbulence, and streamline the flow of molten aluminum. This leads to better thermal efficiency and faster casting times, ultimately improving the overall efficiency of the aluminum foundry.

Reduced Contamination

The Hat Plate and Graphite Ring help reduce the risk of contamination by preventing debris, dust, or air from entering the molten aluminum. This is critical in industries where purity and material integrity are paramount, such as aerospace and automotive manufacturing.

5. Installation and Maintenance

Proper installation and maintenance of the Hot-Top Casting Series components are essential to ensure their longevity and optimal performance. Regular inspection of components such as the Sprue Bush and Distributing Launder is necessary to detect wear and tear. The components should be cleaned and replaced as needed to avoid damage that could impact the quality of the casting process.

Installation Tips:

-

Ensure proper alignment during installation to prevent leaks and ensure smooth flow.

-

Use high-temperature lubricants where required to ease assembly.

Maintenance Tips:

-

Regularly inspect components for signs of wear, especially the Graphite Ring and Hat Plate.

-

Clean components to prevent the buildup of contaminants or metal residues.

6. Frequently Asked Questions (FAQs)

-

What is the function of the Sprue Bush in the Hot-Top Casting Series?

The Sprue Bush directs molten aluminum from the furnace to the casting mold, ensuring smooth and controlled flow. -

Why is the Distributing Launder important in the casting process?

It ensures the even distribution of molten metal, preventing turbulence and maintaining consistent mold filling. -

What materials are used in the Hot-Top Casting Series?

Components are made from ceramic, graphite, high-strength steel, and alloys for heat resistance, durability, and thermal efficiency. -

How does the Hot-top Casting Distributing Launder differ from the regular Distributing Launder?

The Hot-top version is optimized for hot-top casting systems and ensures uniform metal flow while minimizing oxidation. -

What role does the Hat Plate play in the hot-top casting process?

The Hat Plate prevents contaminants from entering the molten aluminum and reduces heat loss during the pouring process. -

Can the Graphite Ring help control the temperature of molten aluminum?

Yes, the Graphite Ring provides insulation and thermal conductivity to maintain the desired temperature of the molten metal. -

How often should Hot-Top Casting Series components be replaced?

It depends on usage, but components should be inspected regularly for wear and replaced when necessary. -

What are the key benefits of using the Hot-Top Casting Series in aluminum foundries?

Enhanced casting quality, improved efficiency, and reduced contamination are among the main benefits. -

Is the Hot-Top Casting Series suitable for all types of aluminum casting?

Yes, it is designed for high-performance applications, particularly in aluminum foundries focusing on quality and efficiency. -

What are the main challenges when using the Hot-Top Casting Series?

Ensuring proper installation and maintaining the components to prevent wear and maintain the flow of molten metal can be challenging without regular inspection.

Conclusion

The Hot-Top Casting Series is a vital component of aluminum foundries, playing an essential role in improving the quality, efficiency, and purity of the casting process. With components like the Sprue Bush, Distributing Launder, Hat Plate, Transition Plate, Graphite Ring, and Hot-top Casting Distributing Launder, this series ensures smooth and precise control over the molten metal, reducing defects and improving overall production outcomes. Proper installation, regular maintenance, and the use of high-quality materials are crucial for maximizing the effectiveness of these components in aluminum casting operations.