An correctly specified Impurity Separation Ring significantly reduces slag and floating contaminants entering downstream moulds and treatment stages, improving ingot quality, cutting scrap and extending the service life of degassing and filtration consumables; when matched to launder geometry, alloy mix and operating routines, ADtech separation rings deliver measurable metallurgical and economic gains while remaining simple to install and maintain.

Introduction and purpose

Foundries handling molten aluminum manage a persistent challenge: surface oxides, dross and other floating debris travel with the metal and can re-enter moulds or damage downstream equipment. An Impurity Separation Ring is a simple refractory insert that intercepts that floating material by creating a controlled annular flow zone where contaminants accumulate and can be removed by skimming. The device protects high-value downstream processes such as degassing, filtration and casting, improving product consistency and cutting process costs. Industry product descriptions and supplier literature show these rings are commonly used in casting crystallizers, hot-top systems and launders to trap surface slag prior to final pour.

What an Impurity Separation Ring is and why it matters

An Impurity Separation Ring, sometimes labelled skim ring, slag ring or skim ring, is usually a circular refractory component installed near an inlet or inside a tundish, launder or hot-top. Metal enters the annular space around or inside the ring. Flow is slowed and partially redirected, which encourages buoyant oxides and light dross to rise to the surface in a controlled pocket instead of travelling downstream with the main stream. The collected material is then skimmed off manually or by mechanical skimmers. Manufacturer documentation and foundry guides show this simple hydrodynamic separation reduces the risk of slag inclusion in cast products and thereby helps meet quality standards for ingots and downstream alloy feedstock.

Why it matters in plain terms

-

Floating contaminants cause surface defects, internal inclusions and machining scrap.

-

Removing these contaminants before degassing and filtration reduces filter loading and rotor wear.

-

A separation ring reduces the chance of a single contaminated pour causing costly rework or rejected batches.

Key operating principles

The separation ring operates by combining three physical effects:

-

Flow diversion and energy dissipation

The ring changes flow direction and reduces stream velocity, which lowers the kinetic energy that would otherwise re-entrain surface material. -

Residence time increase in a calm pocket

By creating an annular or staged flow path, the ring provides extra time for oxides and light debris to float to the top and collect. -

Controlled discharge geometry

A calibrated notch, slot or orifice meters out the metal beneath the surface, so that the exit stream draws from the cleaner sub-surface metal layer rather than the scummed top layer.

These mechanisms are intentionally simple yet very effective in practice. When combined with regular skimming, the ring forms a low-cost barrier that complements degassing and filtration upstream and downstream. Several supplier pages and product briefs describe such flow-conditioning behavior and typical installation contexts.

Specification:

| items | Dimensions | Special dimensions | Package | Special package |

| Flow pipe | 100-2600mm | As drawing | 10pieces/box | As required |

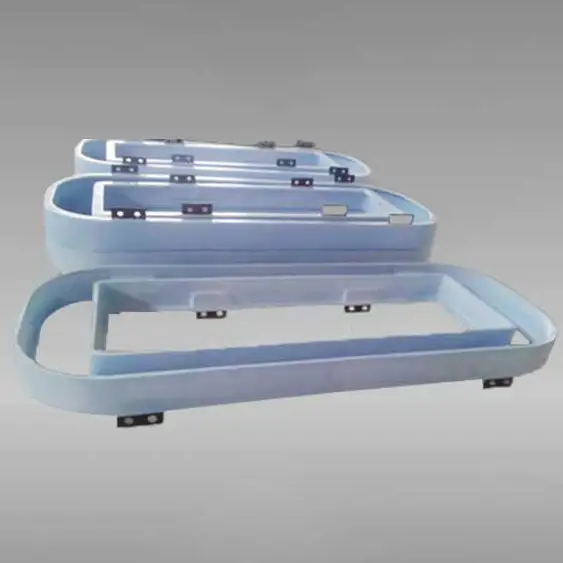

Typical shapes, styles and variants

Impurity Separation Rings come in several practical forms tailored for specific process needs:

Common ring styles

-

Solid weir ring with top crest

A continuous annular block providing a single overflow crest. Best for steady flows with consistent pour heights. -

Adjustable slot ring

A ring with changeable internal plates or notches to tune the slot height and discharge area for variable batch sizes. -

Spreader or flow-smoothing ring

Incorporates an angled lip or integrated spreader plate to diffuse incoming jets and protect downstream filters. -

Multi-pocket baffle ring

Multiple concentric rings or internal baffles inside the ring create staged pockets for heavy-duty flotation and longer residence time.

Specialised variants

-

Coated skim rings

Rings with anti-wetting surface treatments to reduce metal adhesion and ease cleaning. -

Quick-change modular rings

Prefabricated rings that can be swapped without shutting major production lines. -

Integrated skimmer-compatible rings

Rings that include mounting points or cutouts for mechanical skimmers to operate with minimal operator exposure.

Supplier literature frequently lists these options and emphasizes matching the style to the launder or mould geometry for best effect.

Materials and protective coatings

Refractory selection is critical because the ring contacts molten aluminum and skimming operations. Typical material choices include:

Table 1 Typical materials and their attributes

| Material | Key properties | Common use cases |

|---|---|---|

| High-silicon castable refractory | Low wetting tendency, good chemical resistance to aluminum | General-purpose rings for medium duty |

| N17 grade or graphite-based bodies | Good thermal shock resistance, informal supplier references cite N17 for certain rings | Hot-top and crystallizer rings where mechanical robustness is needed. |

| SiC-reinforced alumina | Improved abrasion resistance and thermal cycling tolerance | Heavy-duty launders, high-throughput plants |

| Dense fused alumina or zirconia-enriched bricks | Highest chemical stability and wear resistance | Specialty alloy melts or critical impurity control lines |

Coatings

-

Boron nitride based coatings reduce metal adhesion and make cleaning easier.

-

Proprietary anti-wetting glazes are available from some manufacturers to lengthen service life.

Choose the grade that balances initial cost against expected lifetime, maintenance access and the alloy chemistry handled in the line. Supplier notes commonly recommend N17 or comparable grades for effective impurity separation in hot-top and casting applications.

How the ring interacts with the melt-treatment train

To work effectively, the separation ring is one element in an assembled melt-treatment sequence. Typical placement logic is:

-

Furnace or holding well discharge

-

Initial skimming station (if present)

-

Settling pocket with Impurity Separation Ring to trap residual surface material

-

Degassing unit (rotary gas purging or vacuum) to remove dissolved hydrogen

-

Filtration (foam, plate or cartridge) to capture inclusions

-

Final pouring into mould or tundish

Placing the ring upstream of degassing and filtration concentrates surface debris for removal before the expensive treatment steps, prolonging consumable life and lowering total cost of operations. ADtech and other suppliers show diagrams of launders and hot-top installations that place skim rings immediately prior to degassers and filters for this reason.

Where to place the ring and siting rules

Proper siting makes the difference between modest and excellent results. Follow these pragmatic rules:

-

Position the ring in a calm section of the launder or in a settling pocket that is wide enough to form a gentle U-shaped flow path.

-

Locate skimming access adjacent to the ring so operators can remove accumulated scum quickly without disturbing flow.

-

Ensure the ring crest or slot sits below the desired pour height yet above the point where heavy slag might sink, so the discharge draws from cleaner sub-surface metal.

-

Provide sufficient clearance for manual or mechanical skimmers and for visual inspection.

-

Maintain an upstream flow spreader to break jets that could attack the ring face.

-

Avoid placing the ring immediately at an inlet where direct jet impact will bypass the settling effect.

A short commissioning run with sampling and RPT tests will confirm whether siting needs micro-adjustment. Manufacturer guidance and practical manuals emphasize these placement considerations.

Sizing and selection criteria

Selecting the ring requires balancing flow rates, pour height, alloy and maintenance windows. Consider the following variables:

Input variables

-

Batch mass or pour rate in kg/s

-

Typical pour height or head in mm

-

Launder or tundish cross-section and gross flow area

-

Desired residence time in the calm pocket

-

Skimming frequency and method (manual or mechanical)

-

Alloy reactivity and expected dross load

Table 2 Sizing heuristics

| Production class | Ring inner diameter or slot span | Recommended crest/slot height range | Notes |

|---|---|---|---|

| Small lab or R&D | small ring, 150–300 mm | slot 10–30 mm | Short residence time tolerable |

| Medium foundry | 300–600 mm | slot 20–50 mm | Balance skimming intervals and flow |

| High throughput | 600–1,200 mm or custom multi-pocket | slot 30–100 mm adjustable | Larger annular area to avoid frequent skimming |

Practical approach

Start with a conservative slot that favors cleanliness over throughput then tune the opening and skimming cadence. Record head loss and pour rates at each setting to build standard operating recipes for each alloy family. Suppliers often propose trial sizes and assist with validation.

Installation and commissioning checklist

A well-run installation reduces the chance of early failure. The following checklist covers key steps:

-

Pre-installation inspection of ring and seat for cracks or dimensional variation.

-

Confirm refractory grade and coating, and match to launder lining to avoid differential erosion.

-

Preheat ring and local launder region per supplier recommendations to expel moisture and avoid thermal shock. Industry practice advises controlled ramp-up.

-

Install ring with proper gaskets or mortise seat, ensuring no metal bypass path around the ring.

-

Fit skimmer ports and confirm operator access.

-

Run dry thermal soak and then a cold-flow rehearsal if possible.

-

Execute hot commissioning with instrumented pours, log temperatures and head loss, and collect metallurgical samples upstream and downstream to verify performance.

-

Lock recipes and capture photographic evidence for future audits.

Adhering to these steps reduces early wear and fosters predictable performance.

Operation protocols and daily routines

Daily discipline keeps the ring effective and safe:

-

Pre-shift: visually inspect ring and seating, verify preheat status and instrumentation.

-

During shift: perform skimming at planned intervals or when surface accumulation reaches the preferred control line. Record the mass and nature of skimmings.

-

After each campaign: rapid visual check for spalling or unusual adhesion.

-

Weekly: measure slot dimensions and note progressive wear.

-

Maintain a log linking skimming mass, pour counts and alloy batch details to understand trends.

These routines support continuous improvement and help justify consumable ordering and predictive maintenance.

Maintenance, wear patterns and spare parts planning

Typical wear modes and countermeasures:

Table 3 Wear patterns and remedies

| Wear mode | Cause | Action |

|---|---|---|

| Lip erosion | High local velocity or abrasive inclusions | Fit erosion-resistant inserts; slow pour velocity |

| Surface wetting buildup | Sticky alloys or poor coating | Recoat with anti-wetting glaze; increase skimming frequency |

| Thermal cracking | Inadequate preheat or mechanical shock | Review preheat ramp; replace damaged ring |

| Edge chipping | Impacts during handling | Improve mounting method; use protective carriers |

| Seat wear causing bypass | Gasket failure or misalignment | Replace gaskets; re-machine seat or use refractory rope seal |

Keep an on-site spare ring and a set of gaskets or mounting hardware. Monitor tonnage-per-ring to schedule replacements without emergency downtime.

Performance measurement and validation methods

Objective metrics validate effectiveness:

-

Reduced Pressure Test before and after the ring installation to quantify porosity change.

-

Inclusion counts and size distribution on cross-sectioned parts taken downstream.

-

Head loss vs flow rate curves to determine hydraulic resistance of the ring and pocket.

-

Skimming mass logs to correlate contamination load and filter life.

-

Filter change frequency and rotor wear rates before-and-after trials.

Publish these metrics in commissioning reports and retain them for supplier warranty discussions. Common testing procedures used across foundries help make credible comparisons.

Troubleshooting quick-reference table

Table 4 Troubleshooting matrix

| Symptom | Probable cause | Quick corrective action | Longer-term fix |

|---|---|---|---|

| Slag passing downstream | Slot too large or ring recessed | Reduce slot or use temporary insert | Re-design ring or add secondary baffle |

| Rapid ring wear | High velocity or abrasive inclusions | Reduce pour rate; inspect upstream skimming | Change to SiC-reinforced grade |

| Ring cracking on first use | Moisture trapped or insufficient preheat | Stop pours; allow cool-down and inspect | Review preheat procedure and supplier firing |

| Excessive head loss | Clogging from flux or dross | Clean pocket; increase slot temporarily | Adjust filter/back-up skimming cadence |

| Operator exposure concerns | Poor skimming access or hot surfaces | Provide tools and shields; modify access | Re-engineer skimming port layout |

Record events and corrective actions to build a robust knowledge base.

Environmental, health and safety considerations

A few safety items protect personnel and environment:

-

Preheat to avoid violent steam formation. Industry guidance emphasizes controlled ramp schedules to remove moisture.

-

Provide local exhaust near skimming zones because oxidized slag and flux fumes can emit particulates and irritant gases.

-

Treat skimmed material per local waste regulation; many streams contain recoverable aluminum and should be stored and processed accordingly.

-

Train operators in safe skimming techniques and ensure PPE for molten metal handling.

Comply with local environmental and occupational health rules and document your control measures.

Economic case and ROI snapshot

Impurity Separation Rings are low-complexity items with outsized impact on downstream costs. Typical value drivers:

-

Fewer filter changes and lower rotor wear on degassers.

-

Lower scrap rate from fewer slag inclusions.

-

Reduced machining rework due to improved surface quality.

-

Lower risk of expensive batch rejection.

Table 5 Illustrative ROI calculation

| Item | Example inputs | Outcome (illustrative) |

|---|---|---|

| Annual throughput | 3,000 tonnes | |

| Baseline scrap due to slag inclusions | 1.8% | 54 tonnes lost |

| Post-ring scrap | 0.9% | 27 tonnes lost |

| Metal saved annually | 27 tonnes | at market value |

| Metal value per tonne | $1,800 | $48,600 saved |

| Filter & rotor savings | $15,000 | reduced consumables and maintenance |

| Incremental ring cost and spares | $7,500 | purchase + spares |

| Net annual benefit | $56,100 | payback well under 12 months in many cases |

Quantify site-specific inputs before purchase decisions to obtain accurate payback windows.

Case

Case 1: Medium-sized die casting plant

Problem: Frequent surface blemishes causing 1.5% scrap on cosmetic housings.

Solution: Installed adjustable impurity separation ring plus a skimming schedule.

Result: Scrap reduced to 0.6% in three months. Filter change frequency dropped 30 percent. Payback under nine months.

Case 2: Ingot-producing foundry

Problem: High filter loading and short rotor life from inconsistent pour behaviour.

Solution: Modular separation ring inserted upstream of degasser and paired with a flow spreader.

Result: Rotor wear rates halved and filter life increased by 45 percent; downstream process stability improved and customer complaints fell.

These scenarios reflect typical outcomes experienced across the industry, with actual savings depending on alloy, run cadence and baseline practices.