Adtech Distribution Plates provide a statistically significant improvement in aluminum billet quality by ensuring uniform molten metal distribution and temperature homogeneity during Direct Chill (DC) casting. Cast houses utilizing our high-density calcium silicate plates report a reduction in scrap rates due to uneven grain structures and an increase in casting consistency. If you are a plant manager or engineer seeking to eliminate turbulence and oxidation inclusions in your aluminum logs, the Adtech Distribution Plate is the distinct solution designed for this specific thermal environment.

Understanding the Role of Distribution Plates in DC Casting

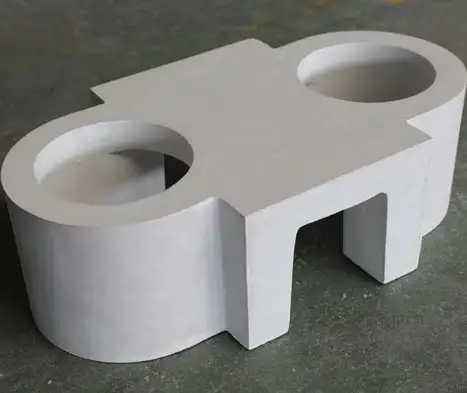

The casting process for aluminum alloys requires absolute precision. A distribution plate is not merely a consumable. It is the final control point before the molten aluminum solidifies. Located inside the hot top header, this component dictates how the liquid metal flows into the mold.

Adtech designs these plates to manage the velocity and direction of the flow. When molten aluminum enters the mold, it must do so without creating turbulence. Turbulence causes oxide films to fold into the melt. These inclusions create weak points in the final product. Our plates utilize specific nozzle designs and hole patterns to laminarize the flow. This ensures that the metal enters the solidification zone calmly.

The Physics of Flow Control

The primary function involves hydraulic management. As aluminum flows from the launder through the downspout, it carries kinetic energy. The distribution plate absorbs this energy. It redistributes the metal radially toward the mold walls. This action flattens the thermal gradient across the billet head.

Without a high-quality distribution plate, the center of the billet often remains too hot while the edges cool too quickly. This thermal stress leads to cracks. Adtech plates ensure the temperature remains consistent from the center to the periphery. This balance is vital for alloys like the 7000 series which are sensitive to thermal shock.

Material Science: Why Calcium Silicate?

We manufacture Adtech Distribution Plates using distinct high-density fiber-reinforced calcium silicate. This material choice is deliberate. It offers specific advantages over traditional refractory materials or lower-grade ceramics.

Thermal Properties and Non-Wetting Behavior

Calcium silicate possesses low thermal conductivity. This property preserves the heat of the molten aluminum. It prevents the metal from freezing prematurely as it passes through the distribution holes. Furthermore, the material is non-wetting to aluminum. The molten metal does not stick to the surface of the plate. This characteristic makes cleaning easier and extends the operational life of the part.

The density of our material is engineered to withstand the erosion caused by high-velocity flow. Low-density plates often degrade, releasing particles into the melt. These particles become inclusions in the billet. Adtech plates maintain their structural integrity throughout the casting campaign.

Comparison of Material Grades

Adtech provides different grades suited for specific casting requirements.

Table 1: Adtech Material Specifications

| Feature | Adtech N17 Grade | Adtech N100 Grade | Standard Refractory |

| Density (g/cm³) | 0.85 | 1.0 | 0.65 |

| Max Service Temp | 800°C | 1000°C | 700°C |

| Thermal Shock Resistance | High | Excellent | Moderate |

| Aluminum Wettability | No | No | Partial |

| Primary Application | Standard Billets | Hard Alloys / Aerospace | General Casting |

Adtech plates function as a critical component of the hot top casting system. They work in conjunction with thimbles, transition plates, and adapter rings. By optimizing the geometry of the distribution plate, cast houses can influence the sump depth. A shallower sump generally results in a better surface finish and more uniform grain structure. Our engineering team customizes the hole pattern to match the specific diameter of the mold and the alloy being cast.

Reducing Solidification Defects

A major issue in aluminum foundries is the formation of “cold shuts” or surface laps. These occur when the meniscus of the aluminum freezes against the mold wall before new metal arrives. The design of the Adtech Distribution Plate directs fresh, hot metal toward the mold wall. This action keeps the meniscus active and prevents surface defects. It is a direct correlation between plate design and surface quality.

Detailed Technical Specifications and Customization

One size does not fit all in aluminum casting. Adtech offers customization services. We machine plates to precise tolerances based on client drawings.

Dimensions and Tolerances

The flatness of the plate is critical. If a plate is warped, it will not seal correctly against the transition plate or the hot top. This leads to metal leakage. Adtech guarantees flatness tolerances within +/- 0.1mm.

We can produce plates for billet diameters ranging from 3 inches to 14 inches and beyond. The thickness of the plate is typically determined by the thermal load it must bear. Thicker plates are used for larger diameters to prevent mechanical failure under the weight of the metal.

Table 2: Common Defect Solutions via Adtech Plates

| Defect Type | Cause Related to Flow | Adtech Solution |

| Center Cracks | uneven cooling / deep sump | Optimized hole pattern to flatten temperature gradient |

| Oxide Inclusions | Turbulent entry flow | Laminar flow design reduces surface agitation |

| Cold Shuts | Low temperature at mold wall | Radial flow directs hot metal to periphery |

| Uneven Grain Size | Variable solidification rate | Consistent thermal distribution ensures uniform grain |

Installation and Operational Best Practices

Proper use of the distribution plate determines its lifespan and performance. Even the best product will fail if installed incorrectly.

Pre-Heating Procedures

Calcium silicate is hygroscopic. It can absorb moisture from the air during storage. If a cold, damp plate contacts molten aluminum at 700°C, the moisture turns to steam instantly. This can cause the plate to crack or explode.

Step-by-Step Pre-Heating:

-

Store plates in a dry environment.

-

Before installation, inspect the plate for shipping damage.

-

Pre-heat the plate to approximately 200°C to 300°C. This drives off any residual moisture.

-

Ensure the plate reaches a temperature close to the casting temperature before the start of the cast. This reduces thermal shock.

Coating Application

While Adtech plates are non-wetting, applying a thin layer of Boron Nitride (BN) coating provides additional protection. This acts as a release agent. It makes the removal of the solidified “butt” easier at the end of the cast. The coating should be applied evenly and allowed to dry completely before use.

Case Study 2023

Evidence of performance is essential for technical buyers. The following case illustrates the tangible benefits of switching to Adtech.

Project: Yield Improvement for 6063 Alloy Billets

Location: Aluminum Extrusion Supplier, Bahrain

Time: April 2023 – October 2023

The Challenge:

A prominent aluminum plant in Bahrain faced issues with their 8-inch billet production. They experienced a high rejection rate due to oxide inclusions and coarse grain structures at the billet center. Their existing distribution plates, sourced from a generic supplier, eroded quickly. This erosion altered the flow dynamics mid-cast.

The Adtech Solution:

Our technical team analyzed their casting parameters. We recommended the Adtech N17 High-Density Distribution Plate. We also modified the nozzle aperture size to reduce the velocity of the metal entering the mold.

Implementation:

The plant installed the N17 plates on one casting pit while maintaining the old plates on a second pit for comparison. The trial ran for six months.

The Results:

-

Inclusion Reduction: The scrap rate due to inclusions dropped by 18% in the pit using Adtech plates.

-

Lifespan Extension: The generic plates required replacement every 80 casts. Adtech plates lasted for an average of 140 casts.

-

Cost Savings: Despite the slightly higher unit cost of the Adtech plate, the reduction in scrap and the extended lifespan resulted in a net saving of $45,000 over the six-month period for that single pit.

This case confirms that superior material density and precise engineering directly translate to profitability for cast houses.

The Connection Between Distribution Plates and Downstream Processing

The quality of the billet produced in the cast house dictates the efficiency of the extrusion press. If a billet has a non-uniform grain structure, the extrusion speed must be reduced. This slows down the entire factory.

Adtech Distribution Plates enable faster extrusion speeds. By ensuring a homogenous billet structure, the extrusion press can operate at higher pressures without tearing the metal. This is a holistic view of production. Investing in the right consumable at the casting stage pays dividends at the extrusion stage.

Integration with Molten Metal Filtration

Distribution plates are the final step. However, they work best when the metal is already clean. Adtech recommends pairing these plates with our Ceramic Foam Filters (CFF). The CFF removes the bulk of the inclusions before the metal reaches the distribution plate. The plate then handles the flow control. This dual-approach guarantees aerospace-grade quality.

Advanced Troubleshooting Guide

Operators often blame the metal or the mold when the issue lies with the distribution mechanism.

Scenario 1: Metal Leakage around the Plate

This usually indicates a flatness issue or debris between the plate and the seat. Ensure the seating area is perfectly clean. Check the Adtech plate on a surface plate to verify flatness.

Scenario 2: Rapid Erosion of Holes

If the holes enlarge quickly, the metal velocity might be too high. Alternatively, the metal temperature might be exceeding the rating of the plate. Switch to Adtech N100 grade for higher temperature resistance.

Scenario 3: Cracking on First Use

This is almost always a pre-heating failure. The thermal shock of liquid aluminum hitting a cold ceramic plate creates immense stress. Review the pre-heating protocol immediately.

Comparative Analysis: Adtech vs. Global Competitors

The market contains various options. Why choose Adtech?

Table 3: Competitive Analysis

| Metric | Adtech | Competitor A (Low Cost) | Competitor B (Premium) |

| Material Integrity | High Density Fiber Reinforced | Standard Calcium Silicate | Fused Silica |

| Customization Speed | 7-10 Days | Fixed Sizes Only | 4-6 Weeks |

| Technical Support | 24/7 Engineering Access | None | Business Hours Only |

| Price to Value | Optimal | Low Cost / Low Life | High Cost |

Adtech balances performance with cost. We do not sell the cheapest plate on the market because cheap plates fail. We sell the most cost-effective plate when calculated on a “cost per ton of cast aluminum” basis.

Adtech Distribution Plates (N100 Grade): Technical FAQ

1. What is the maximum temperature the Adtech Distribution Plate can withstand?

2. Can these plates be reused?

3. Do I need to apply Boron Nitride (BN) coating?

4. How do I store these plates?

5. Can Adtech customize the hole pattern?

6. What causes the plate to break during casting?

7. Is the material asbestos-free?

8. How does this plate improve billet surface finish?

9. What is the lead time for a custom order?

10. Does this product work for alloys other than aluminum?

The Future of Aluminum Casting with Adtech

The industry is moving toward harder alloys and larger billet diameters. This shift places greater stress on consumables. Adtech is constantly evolving our material formulas. We are currently testing nano-reinforced composites that offer even higher erosion resistance.

Our commitment is to the caster. We understand that a downtime of one hour costs thousands of dollars. Adtech Distribution Plates are built to provide peace of mind. They are the silent guardians of your casting quality.

Ensuring Sustainability

Modern foundries must also consider waste. Adtech plates last longer. This means fewer plates are sent to the landfill annually. By improving yield and reducing scrap aluminum, we also help reduce the energy footprint of the plant. Remelting scrap aluminum consumes significant energy. Getting it right the first time is the greenest way to operate.

Optimizing Your Supply Chain

Relying on inconsistent suppliers creates risk. Adtech maintains a robust global inventory. We understand the logistics of shipping heavy, fragile ceramics. Our packaging is reinforced to ensure plates arrive in perfect condition, whether you are in Bahrain, Texas, or Germany.

Technical Partnership

When you buy an Adtech product, you gain a partner. Our team assists with drawing optimization. If you are seeing specific defects, send us photos. We can often diagnose the flow issue and adjust the plate design to solve it. This level of service is rare in the consumables market.

Final Recommendations for Procurement

When evaluating your distribution plate supplier, look beyond the unit price. Calculate the Total Cost of Ownership (TCO). Include the cost of scrap. Include the cost of downtime for changeovers. Include the value of technical support.

Adtech stands ready to prove our value. We invite you to test our plates against your current standard. The results in the cast house will speak for themselves.