For optimal aluminum continuous casting, selecting the correct caster tips and nozzles is the single most critical factor in controlling sheet gauge, surface quality, and microstructure. High-performance ceramic fiber tips (specifically N17 and high-silicon variants) are the industry standard for twin-roll casting, offering superior thermal insulation, non-wetting properties against molten aluminum, and resistance to thermal shock. Data from industrial trials indicates that using precision-machined, nano-reinforced caster tips can reduce surface defects like ripple marks and edge cracks by up to 30%, while extending service life to over 48 hours per set. The key to maximizing throughput and quality lies in matching the tip stiffness and thermal conductivity to your specific alloy grade (e.g., 1xxx vs. 5xxx series) and maintaining a strict preheating protocol of 260°C to eliminate absorbed moisture before installation.

1. The Critical Role of Caster Tips in Twin-Roll Casting

In the twin-roll continuous casting process (TRC), the caster tip (also known as the nozzle or injector) serves as the final interface between the molten metal distribution system and the water-cooled rolls. Its primary function is not merely to deliver metal but to condition the flow, ensuring a laminar, uniform wavefront across the entire width of the casting rolls.

Why Precision Matters

If the caster tip fails to maintain dimensional stability, the gap (aperture) between the tip lips will vary. A variance of even 0.1mm can lead to uneven cooling, resulting in “hot spots” or “cold shuts.” The ADtech brand focuses on solving these specific fluid dynamic challenges by using materials that resist erosion and maintain rigidity under the hydrostatic pressure of the headbox.

Core Functions of the Nozzle Assembly:

-

Flow Distribution: Converting turbulent flow from the headbox into a laminar stream.

-

Temperature Maintenance: preventing premature solidification before the nip point using low thermal conductivity materials.

-

Width Control: Determining the precise casting width through adjustable edge dams and spacers.

2. Types of Aluminum Casting Tips: Materials and Performance

The choice of material for your nozzle determines the consistency of your casting campaign. The two dominant material categories are Ceramic Fiber and N17 (High-Density Calcium Silicate).

Ceramic Fiber Caster Tips

These are the most common solution for standard aluminum sheet production. Manufactured using a vacuum-suction forming process, they are lightweight and possess excellent insulation properties. ADtech’s ceramic fiber tips are often reinforced with a nano-scale coating to prevent fiber delamination, which causes inclusions in the final sheet.

-

Best for: 1xxx, 3xxx, and 8xxx series alloys.

-

Key Advantage: Excellent flexibility allows the tip to compress slightly under roll force without cracking, maintaining a tight seal.

N17 and Hard Rigid Tips

For more demanding applications, such as high-magnesium alloys (5xxx series), rigid boards like N17 are preferred. These are machined from high-density blocks rather than vacuum formed.

-

Best for: High-speed casting and harder alloys (e.g., 5052, 5182).

-

Key Advantage: Superior resistance to erosion and “bowing” across wide widths (up to 2000mm+).

Comparison: Ceramic Fiber vs. N17 Rigid Board

| Feature | Ceramic Fiber Tips (Soft/Semi-Hard) | N17 Rigid Board Tips (Hard) |

| Material Base | Alumina-Silicate Fiber + Binder | Graphite-Reinforced Calcium Silicate |

| Density (g/cm³) | 0.45 – 0.60 | 0.85 – 1.00 |

| Thermal Conductivity | Very Low (< 0.12 W/m·K) | Low (< 0.20 W/m·K) |

| Machinability | Low (molded shape) | High (CNC machined to tolerance) |

| Flexibility | High (Compressible) | Low (Rigid) |

| Primary Use | Standard Foil Stock, Cans | Architectural Sheets, Auto Body |

3. Optimizing Flow: Internal Baffles and Spacers

A casting nozzle is rarely a simple hollow tube. Inside, it contains a sophisticated arrangement of baffles and spacers.

-

Baffles: These internal structures disrupt the kinetic energy of the incoming molten aluminum. By forcing the metal to wind through a “serpentine” path, baffles ensure that the velocity is uniform at the exit lip. Without baffles, the center of the sheet would receive faster, hotter metal than the edges, leading to center-line segregation.

-

Spacers: These rigid blocks maintain the internal gap (aperture) of the nozzle tip. They must be made of materials that do not react with aluminum, typically dense fused silica or high-alumina ceramics.

Pro Tip for Operators:

When casting wide sheets (>1500mm), increase the number of internal spacers to prevent the nozzle lips from bulging outward due to metallostatic pressure. A bulging lip causes the sheet to be thicker in the middle, a defect known as “crown.”

4. Common Defects Related to Nozzles and Troubleshooting

Poor tip condition is the root cause of nearly 40% of casting defects in TRC. Identifying the link between the defect and the nozzle condition is essential for rapid troubleshooting.

Table 2: Troubleshooting Nozzle-Related Casting Defects

| Defect Symptom | Potential Nozzle Cause | Immediate Solution |

| Start-up Freezing | Tip temperature too low; insufficient preheating. | Increase preheat time/temp; check for air gaps in insulation. |

| Stripes / Streaks | Blockage or snag in the nozzle lip; oxide buildup. | Inspect tip lips for damage; use a better release agent (Boron Nitride). |

| Uneven Gauge | Nozzle lip deformation (bowing/warping). | Check spacer placement; switch to a higher density tip (N17). |

| Edge Cracks | Cold metal at the nozzle edges; “Dog-bone” thermal profile. | Improve edge insulation; adjust edge dams to prevent heat loss. |

| Inclusions | Tip erosion; refractory fibers peeling off into the melt. | Switch to nano-coated tips; ensure smooth surface finish (Ra < 3.0). |

5. Technical Specifications for ADtech Caster Tips

To ensure you are selecting the right component, refer to the technical parameters below. These standards comply with global aerospace and foil packaging requirements.

| Parameter | Specification |

| Composition | Al2O3 (45-55%) + SiO2 (45-50%) |

| Service Temperature | Max 1260°C (Continuous: 800°C – 1000°C) |

| Dimensional Tolerance | ± 0.5 mm (Width), ± 0.2 mm (Gap) |

| Loss on Ignition (LOI) | < 6% |

| Coating Compatibility | Compatible with Boron Nitride (BN) & Graphite sprays |

| Surface Hardness | Adjusted based on application (Soft/Medium/Hard) |

6. Installation and Replacement Procedure

Improper installation is the leading cause of “breakouts” (molten metal spilling). Follow this strict protocol to ensure safety and performance.

Step 1: Preparation

Ensure the steel shell (the metal holder for the ceramic tip) is clean and free of old refractory glue or aluminum splash. Any debris will cause the ceramic tip to sit unevenly, creating stress points.

Step 2: Preheating (Crucial Step)

Ceramic fiber materials naturally absorb moisture from the air. If a cold, damp tip touches molten aluminum (approx. 680°C), the water turns to steam instantly, causing the tip to explode or crack.

-

Protocol: Place the new tips in a drying oven.

-

Cycle: Ramp up to 200°C for 2 hours, then hold at 260°C for at least 4 hours.

-

Storage: Keep in a dry box at >100°C until the exact moment of installation.

Step 3: Assembly

Apply a thin layer of refractory sealant (like ADtech’s high-temp mastic) between the tip and the headbox. Tighten clamps uniformly—do not over-torque, as this can fracture the ceramic board before casting begins.

Step 4: Surface Coating

Apply a layer of Boron Nitride (BN) spray to the lips of the nozzle. This non-wetting agent prevents the aluminum from sticking to the ceramic and ensures a smooth release.

7. Case Study: Optimization of 5052 Alloy Casting in Henan (2024)

Location: Henan Province, China (Aluminum Industry Hub)

Date: March 2024

Client: A mid-sized aluminum rolling mill specializing in automotive heat shields.

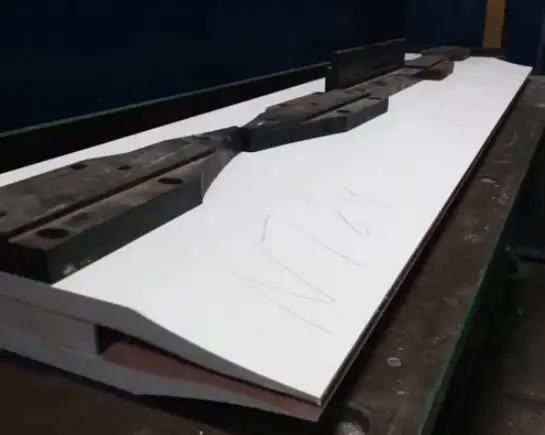

The Problem:

The client was producing 5052 aluminum alloy (a high-magnesium grade) using standard vacuum-formed caster tips. They experienced frequent “drag marks” and surface tearing on the strip surface. Consequently, they had to stop the casting line every 12 to 14 hours to replace the nozzle, significantly hurting their OEE (Overall Equipment Effectiveness). The soft tips were eroding too quickly under the flow of the abrasive magnesium-rich alloy.

The Solution:

ADtech engineers recommended switching to a Hardened N17-style Rigid Board Nozzle with a specific internal baffle design optimized for high-magnesium flow.

-

Material Change: Replaced standard ceramic fiber with high-density, graphite-reinforced calcium silicate (N17 equivalent).

-

Design Change: Implemented a “3-chamber” baffle design to reduce turbulence at the exit lip.

The Results:

-

Extended Lifespan: The casting campaign duration increased from 14 hours to 72 hours continuous operation.

-

Defect Reduction: Surface drag marks were virtually eliminated, reducing the scrap rate by 18%.

-

Cost Savings: Although the rigid N17 tips cost 25% more initially, the reduction in downtime and scrap resulted in a net savings of $45,000 USD over the first quarter of 2024.

Launder Systems and Distribution

The caster tip is just the end of the line. The quality of the metal entering the tip depends on the launders (channels) and filtration boxes. If the launder lining sheds particles, those particles will clog the caster tip baffles, ruining the cast. Always pair high-quality tips with fused silica launder liners.

Boron Nitride Coatings

Often searched as “release agents for casting,” Boron Nitride is the best friend of a caster tip. It acts as a lubricant at high temperatures. Unlike graphite, which can burn off or contaminate the melt with carbon, BN remains stable and inert.

Twin-Roll vs. Belt Casting Tips

While this article focuses on Twin-Roll Casting (TRC), Belt Casters (like Hazelett) also use injection nozzles. However, belt caster nozzles operate under different thermal conditions and are typically much wider and subjected to less compressive force than TRC tips.

8. Continuous Caster Tips & Nozzles: Technical FAQ

1. What is the main difference between “Hard” and “Soft” caster tips?

2. Why do caster tips sometimes explode during startup?

3. How often should I replace my caster tips?

4. Can I use the same nozzle for 1xxx and 5xxx series alloys?

5. What is the best coating for caster tips?

6. What causes “ears” or “ridges” on the cast strip?

7. How does ADtech ensure the quality of its caster tips?

8. What is the maximum width for a single caster tip?

9. How do I prevent the nozzle from blocking during casting?

10. Why is the thermal conductivity of the tip material important?

9. Conclusion and Recommendations

The humble caster tip is a high-technology component that dictates the profitability of an aluminum casting line. Whether you are producing ultra-thin foil stock or robust automotive sheets, the interaction between the nozzle material and the molten alloy is the determining factor for quality.

For modern rolling mills, upgrading to nano-reinforced ceramic fiber tips or precision-machined N17 boards is one of the most cost-effective methods to improve yield. By following the maintenance and installation protocols outlined above—specifically the rigorous preheating regime—operators can eliminate common defects and achieve consistent, world-class casting results.

ADtech remains committed to advancing the metallurgy of consumables, providing casting tips that not only withstand the heat but also deliver the precision required for today’s high-performance aluminum market.