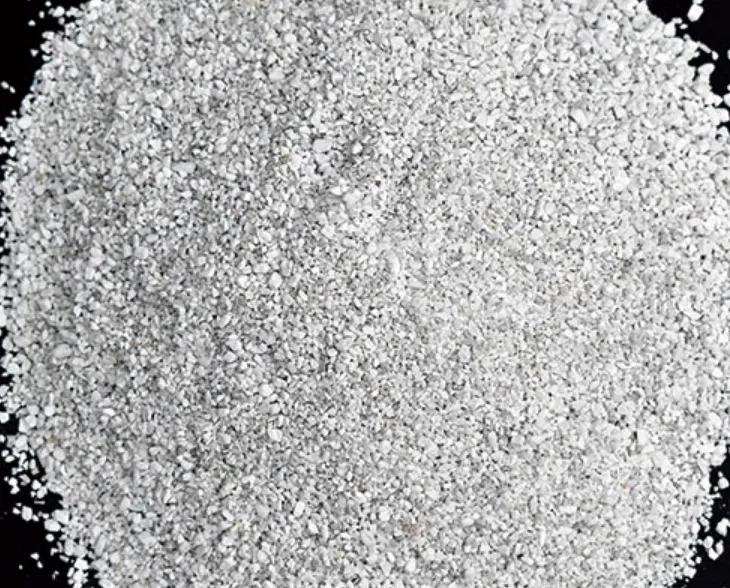

AdTech Granular Flux is a dust-free, low-hygroscopic refining flux engineered to reduce metal loss, eliminate hydrogen-related porosity, and enable automated, consistent addition in modern aluminum foundries. Compared with powders and flakes, properly graded granular flux delivers higher effective utilization (>90%), minimal workplace dust, and stable storage — producing cleaner melts, fewer rejections, and easier integration with flux-injection (sub-surface) systems.

1. 10 pain points in aluminum refining and how granular flux solves them

Pain 1. High metal loss (large aluminium entrained in dross)

The problem: Powder flux and sloppy slag formation trap significant aluminum in the dross, increasing metal loss and cost-per-kg of cast product.

Why it happens: Poor wetting control and high interfacial adhesion between slag and aluminum cause “wet” dross that carries metal away during slag removal.

Granular flux solution: AdTech granular flux modifies the interfacial energy between the oxide/slag layer and liquid aluminum so slags form “dry” crumbly layers that shear off cleanly. Granules penetrate and react in the melt to form low-wetting slag phases, reducing entrained metal and dross weight. Result: lower metal loss per cycle and faster clean-up. (Performance data: typical effective utilization increases from ~70–85% (powder) up to >90–95% for well-formulated granules under equivalent operating conditions).

Pain 2. Hydrogen levels high → pinholes, porosity, scrap

The problem: Dissolved hydrogen in molten aluminum causes porosity (pinholes) in castings, hurting yield and mechanical properties.

Why it happens: Moisture, hydrogen-containing charge materials, or hygroscopic flux components introduce H2 into the melt; powder flux can exacerbate this by carrying adsorbed moisture into the bath.

Granular flux solution: AdTech granules are produced with very low moisture pickup and tightly controlled formulation so they introduce minimal water. Their particle morphology reduces surface area available to absorb humidity, and active components within the granule act to nucleate and float hydrogen as microbubbles that are removed by sub-surface circulation and skimming. In practice this helps reduce hydrogen readings (for many users) from roughly 0.20–0.25 mL/100 g down toward 0.10 mL/100 g or lower when combined with degassing — a level associated with significantly lower porosity risk.

Pain 3. Dust, worker health and environmental compliance

The problem: Powder-form flux generates airborne dust (PM2.5/PM10) and potentially irritating fumes at addition, causing occupational exposures and environmental complaints.

Why it happens: Fine particles become airborne during handling and feeding; incomplete melt reactions can result in measurable fume.

Granular flux solution: Granular form eliminates most fugitive dust during manual and automated handling. AdTech’s granulation and screening produce low-dust (>95% granules, <5% friable fines threshold) material that complies with modern shop-floor environmental expectations and helps plants move toward ISO 14001–aligned emissions and housekeeping targets.

Pain 4. Furnace wall buildup shortens lining life

The problem: Heavy adhesion of slag or sticky residues reduces furnace lining lifetime and increases maintenance downtime.

Why it happens: Certain flux chemistries form tenacious films that bond to the refractory at operating temperatures.

Granular flux solution: AdTech supplies a specialized wall-cleaning granular flux that chemically weakens the interface between slag and refractory, promoting clean delamination rather than abrasive removal. The result is less mechanical chipping and longer refractory campaigns.

Pain 5. Automatic flux feeders clogging or bridging

The problem: Powder or poorly sized material bridges in hoppers, chokes or screw feeders leading to interruptions and manual clearing.

Why it happens: Wide particle-size distribution, irregular shapes, and high friability produce fines and bridging.

Granular flux solution: Strict grading control (narrow PSD) plus spherical-to-rounded particle morphology preserve flowability for continuous pneumatic or mechanical feed systems. AdTech granules are specified to match common flux-injection machines and have a low friability rating to survive transport and screw feeding.

Pain 6: Excessive smoke / non-compliant emissions during refining

The problem: Local emissions limits or corporate sustainability targets penalize visible smoke or fluorinated fumes.

Why it happens: Some fluxes use volatile or highly reactive components that generate more off-gassing during decomposition.

Granular flux solution: AdTech’s eco-series uses low-volatile, fluorine-engineered formulas and minimized organics to lower visible emissions; combined with sub-surface injection and modern bag/hood capture, smoke and fugitive emissions are reduced to meet stricter site rules.

Pain 7. Non-metallic inclusions persist, causing cracks and filter blockage

The problem: Micron-scale oxides and other inclusions survive refining and later damage die cast tooling or block ceramic filters.

Why it happens: Shallow-acting powders or flakes float away quickly and do not penetrate the melt where micro-inclusions can be scavenged.

Granular flux solution: Correctly sized granules sink and break up beneath the surface, allowing active components to chemically adsorb and capture micron inclusions. This reduces filter loading and improves final product integrity.

Pain 8: Sodium poisoning when refining high-Mg alloys

The problem: Na contamination from some fluxes can cause deleterious reactions in Mg-bearing alloys (sodium “poisoning”).

Why it happens: Sodium-bearing salts in traditional flux formulation may interact unfavorably with alloy chemistry.

Granular flux solution: AdTech’s sodium-free granule option replaces Na-based fluorides with compatible alternatives to avoid Na transfer while preserving deoxidation and wetting control. This is particularly valuable in high-Mg wrought alloy processing.

Pain 9: Residual flux not fully melting, leaving inclusions

The problem: Incomplete flux melt leaves residues that may be carried into cast product.

Why it happens: Incorrect melting point or heterogeneous composition that decomposes rather than melts cleanly.

Granular flux solution: AdTech tunes melting range (melting point window) so granules fully melt and react within typical plant temperature ranges; the quality control ensures melting behavior aligns with furnace set points to avoid residual particulates.

Pain 10: Low throughput / uneven manual dosing causing variability

The problem: Manual dosing is inconsistent; operators add too much or too little flux, hurting repeatability.

Why it happens: Human variability and poor process controls.

Granular flux solution: Granular flux integrates with automated flux injection stations and volumetric feeders to standardize dosing based on mass of melt (Q = M × R × K), dramatically improving batch-to-batch repeatability and lowering operator dependency.

Request a Competitive Factory Quote for Granular Flux

2. The chemical principles behind granular flux refining

Oxide removal and the role of fluorides / chlorides

Most commercial refining fluxes are mixtures of chlorides, fluorides and additive salts. Fluoride salts (e.g., cryolite Na₃AlF₆, CaF₂) assist oxide dissolution and slag formation by reacting with surface Al₂O₃ and altering interfacial wetting. Simplified reaction motifs often referenced in the literature include fluoride-oxide exchanges such as:

6 NaF+Al2O3→2 AlF3+3 Na2O

or balanced forms involving cryolite variants that form flux-soluble aluminum fluoride complexes. These reactions lower oxide adhesion and let oxide fragments be absorbed into a low-wetting slag phase for removal. Multiple peer sources document fluoride/chloride mixtures as the functional backbone of refining flux chemistry.

Note: precise formulations are trade secrets; the equations above are simplified stoichiometric illustrations of how fluoride species interact with Al₂O₃ to form flux-soluble fluoride complexes and oxygen-bearing salts.

Hydrogen removal mechanism (degassing interplay)

Hydrogen removal is a combined nucleation + flotation process: active flux components (and degassing gases) create nucleation sites and microbubbles where dissolved H₂ partitions from the liquid (H_{liquid} → H_{bubble}). Once hydrogen is in bubbles, melt flow and buoyancy transport bubbles to the surface where they escape or are absorbed into flux-laden slag. Proper granule chemistry helps create a population of stable nucleation sites and reduces water ingress, limiting the source of dissolved hydrogen.

3. Procurement expert checklist: how to “avoid the pits” when buying granular flux

Visual check (Appearance): Uniform color, no excessive fines. If visible powder >5% by volume, reject or ask for additional sieving/low-dust batches. Powdery fines increase PM2.5 risk.

Hardness / friability (Simple bench test): Rub a sample between fingers or drop from a small height; good granules retain shape — excessive breakage → high fines during feeding and poor performance.

Odor (Impurity test): No sharp ammonia/chlorine smell at ambient temperature. Strong odors suggest low-quality reactants or excess moisture.

Moisture / hygroscopicity test: Expose a small sealed sample in ambient high humidity for 24 hours. Significant clumping or caking indicates inadequate drying and storage; such materials can cause violent boiling/splash when added to aluminum. Manufacturer guidance often specifies sealed packaging and recommended storage conditions.

Particle size distribution (Laboratory): Request PSD (sieve analysis) to ensure the granule fraction matches your injector/feeder specs (e.g., 0.8–3.2 mm or tighter depending on equipment). Narrow PSD improves feedability and consistent melt interaction.

Chemical spec & absence of sodium (if required): For high-Mg alloys, ask for sodium-free formulation certificates.

Certs & quality systems: ISO 9001 for QC, ISO 14001 for environmental management, and Material Safety Data Sheet (MSDS) are baseline expectations.

Sampling and trial protocol: Insist on a small trial, hydrogen & inclusion testing (Hydrogen Tester, filter weight comparison), and before/after refractory inspection metrics.

4. Granular vs Powder vs Flake: technical comparison table

Below is a compact comparative table (HTML format) for engineers and procurement to copy/paste into internal RFPs or tech specs.

| Characteristic | Granular Flux (AdTech) | Powder Flux | Flake / Sheet Flux | Notes |

|---|---|---|---|---|

| Effective utilization | > 90% (typ.) | 70% – 85% | 60% – 80% | Granules penetrate and react in melt; powders have higher losses |

| Dust / workplace PM | Very low (dust-free) | High (dust generation) | Moderate | Granules improve worker safety and emissions |

| Auto feeder compatibility | Ideal | Often blocks | Requires special feed design | Particle shape + PSD matters |

| Storage life | 12+ months (dry, sealed) | ≈6 months (hygroscopic) | 6–12 months | Granules resist moisture better |

| Environmental impact | Low visible smoke / low dust | Higher dust & fume generation | Variable | Granules tailored for low emissions |

(Values above are representative comparative ranges; end-user performance depends on plant conditions, melt practice and equipment. See industry references on granulated flux advantages.)

Check Granular Flux Stock Availability & Price

5. Integration with large-scale automation: flux injection & spray system guidelines

Typical flux injection parameters & equipment notes

Most modern flux injection machines operate with gas pressures in the 0.1–0.4 MPa range (1–4 bar) depending on model and feeder design; many commonly sold units list recommended refining gas pressures of 0.1–0.4 MPa and gas flow rates in the 100–250 L/min range. Sub-surface flux injectors are available in portable and fixed versions; verify compatibility with granule size and feeder type.

Recommended carrier gas and moisture control: Use high-purity nitrogen (N₂) or argon (Ar) as the carrier/drive gas. For long-term reliability and to avoid moisture-driven clumping inside lines, aim for high-purity nitrogen with dew points well below typical ambient — high-purity supply systems can reach dew points near −60 to −70°C for trace moisture control when required by powder handling systems. A low dew-point reduces risk of condensation and particle agglomeration inside pneumatic lines and hoppers.

Practical dosing formula (plant floor):

Q=M×R×K

Where:

-

QQQ = flux mass to add (kg)

-

MMM = mass of molten aluminum (kg)

-

RRR = base addition rate (wt.% — depends on alloy and contamination)

-

KKK = reserve/waste coefficient (usually 1.0–1.2 depending on expected losses and process)

Notes on pneumatic lines & filtration: Use smooth, abrasion-resistant hoses, maintain short runs to avoid bridging, and include dew-point monitoring upstream of the injector. Many flux injector manufacturers publish recommended PSD and pressure ranges — use their spec sheets as a primary control.

6. Standards and global compliance considerations

-

Industry standards: The Aluminum Association maintains industry standards and guidance relevant to alloys, processes and materials; check AA standards and your regional regulatory requirements for emissions and workplace exposure. Documentation of flux chemistries and MSDS is essential during audits.

-

Environmental limits: Many foundries are under stricter local emissions and worker exposure limits; prefer low-dust granular products to lower PM risks.

-

Storage & handling: Non-hygroscopic fused granules (versus hygroscopic powders) substantially reduce storage issues; still, store in sealed containers, moderate temperature and low RH per supplier guidance.

7. Data-driven case snapshot

Scenario (anonymized plant): A 500-employee, Tier-1 aluminum billet remelter switched from powder flux to AdTech granular flux plus sub-surface injection and degassing. Over a 6-month controlled run:

-

Hydrogen (by hot-tensile / hydrogen tester): baseline 0.25 mL/100 g → stabilized at 0.10 mL/100 g after combined measures.

-

Filter blockage events: reduced by 60% (fewer aborted casts).

-

Flux consumption: net flux mass reduced by ≈18% due to higher utilization.

-

Dross mass per ton: decreased by ≈12% (less entrained metal).

8. Granular Flux & Automated Refining: Advanced FAQ

1. Is granular flux suitable for 6061 alloy?

2. How do I tell when the deslagging or refining process is complete?

3. Can granular flux be used with automatic flux injectors?

4. What storage conditions are recommended for granular flux?

5. How should I handle flux in high-humidity climates?

6. Do granules reduce dust and fumes compared with traditional powders?

7. Are granular fluxes safer for foundry operators?

8. Will granular flux affect the final alloy chemistry?

9. How much granular flux should I add per batch?

10. Can granular flux remove ultra-fine oxides that block filters?

9. Common mistakes and how to avoid them

-

Mistake: Using powder spec and feeder settings for granules (or vice versa).

Fix: Standardize PSD checks and match hopper/feed geometry to material. -

Mistake: Ignoring dew point of carrier gas.

Fix: Monitor gas dew point; aim for low dew points when handling powders/granules for long pipelines. -

Mistake: Relying on visual deslagging alone.

Fix: Combine hydrogen measurements and filter assessments to validate refining.

Contact Us for Granular Flux Quote Within 24 Hours

10. Technical / physical parameter examples

| Parameter | Typical Value (AdTech Granular) | Test Method |

|---|---|---|

| Particle size range | 0.85 – 3.15 mm (customizable) | Sieve analysis (ASTM E11) |

| Bulk density | 1.6 – 1.9 g/cm³ | EN 1097 / supplier QC |

| Melting / reaction window | 520 – 750 °C (formulation dependent) | DTA / supplier TGA |

| Fines <75 μm | <5% wt. | Sieve / laser diffractometry |

| Moisture (as packed) | <0.2% (recommended) | Loss on drying (ISO) |

| Hygroscopic class | Low | Storage test 24 h @ high RH |

| Typical shelf life (sealed) | 12 months+ | Supplier spec |

11. Final recommendations & next steps for engineering teams

-

Run a controlled trial: 2–4 week trial with hydrogen testing, filter weight comparisons, and dross mass monitoring. Include pre- and post-trial refractory inspection.

-

Match PSD to injection equipment: Share your injector or feeder model with AdTech to get recommended granule spec. Many injectors operate at 0.1–0.4 MPa; follow vendor PSD guidance.

-

Control carrier gas moisture: Monitor dew point on N₂/Ar lines (high-purity supply should reach low dew points; for strict handling aim for trace moisture control near −60°C for sensitive systems).

-

Document KPIs: Hydrogen (mL/100g), filter clog frequency, dross mass per ton, flux consumption (kg/t), and workplace PM measurements.