How to optimize rotary jet degassing process for degassing units part C

How to optimize rotary jet degassing process for degassing units part C

3.2 Influence of bubble diameter on the gas-liquid two-phase flow field

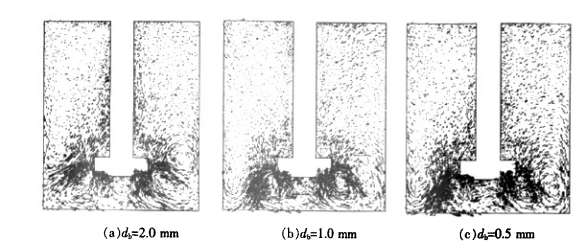

Figure 4 shows the liquid phase velocity distribution of a certain longitudinal section (0=0.) in the degassing unit corresponding to different bubble diameters, in which the degassing unit is square, and the clearance from the bottom is C=150 mm.

Figure 4. Liquid phase velocity distribution in a longitudinal section of the degassing unit corresponding to different bubble diameters

It can be seen from Fig. 4 that the effect of bubble size on the liquid phase velocity field in the degassing unit is mainly manifested in the degree of downward deflection of the radial jet. When the diameter of the bubble is larger, the buoyancy of the bubble during the movement is relatively larger, and the upward drag force exerted by the bubble on the liquid phase is relatively larger, so the downward deflection of the radial jet is weakened. But in general, the distribution of the liquid phase velocity field in the degassing unit is similar.

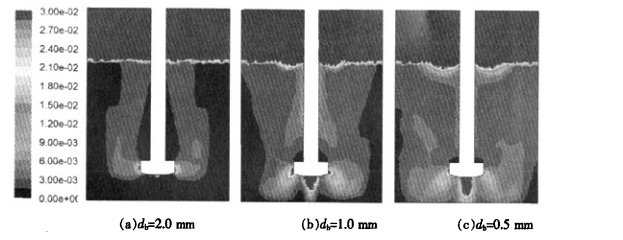

Figure 5 shows the gas volume fraction distribution in a vertical section of the degassing unit corresponding to different bubble diameters, considering 45. The gas distribution on the longitudinal section of the phase angle is worse than that of the 0° phase angle, so only 45 is given here. The longitudinal section where the phase angle is located. The parameters of rotary injection are the same as in Fig. 4.

Fig. 5 Distribution of gas volume fraction in a longitudinal section of degassing unit with different bubble diameters

By comparison, it is found that the bubble size has a great influence on the volume distribution of the gas phase in the degassing unit. After the large-diameter bubbles are blown into the aluminum melt approximately in a horizontal direction, most of them gather around the rotating rod and move up along the rotating rod until the free liquid surface escapes, resulting in very little gas content in the bottom and side walls of the degassing with nitrogen, even no gas exists, resulting in poor hydrogen removal effect of aluminum melt in this part of the region. With the decrease of the bubble diameter, the gas distribution in the degassing unit, especially the bottom and side walls, is effectively improved, the contact area and contact time between the aluminum melt and argon are increased, and the hydrogen removal effect is improved. This is consistent with the conclusion obtained by Anderson's practice.