For applications that need a balance between bulk particulate removal and sustained flow, 20 PPI (20 pores per inch) filter foam is the best general-purpose choice: it provides stable permeability, robust mechanical strength, and easy maintenance while capturing coarse-to-medium particles in liquids and gases. For molten aluminum casting, cleanroom air handling, aquarium prefiltration, and many industrial fluid-filtration tasks, a properly specified 20 PPI reticulated foam delivers strong performance and cost-effectiveness when installed and maintained correctly.

1. What “20 PPI” means and how it’s measured

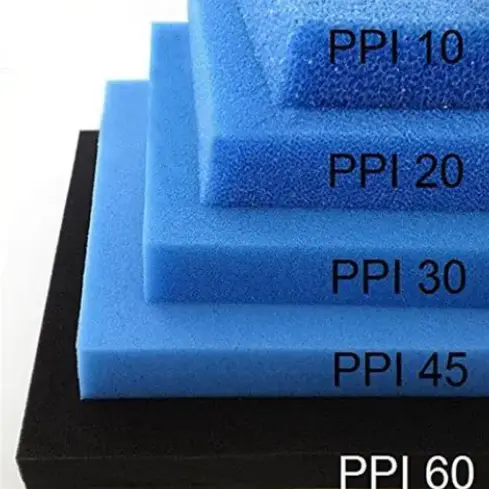

“PPI” stands for pores per inch — a simple visual and functional metric describing how many open cells appear along one linear inch of reticulated foam. A 20 PPI foam therefore has about twenty pore openings per linear inch; that value correlates with pore diameter, open area fraction, and airflow or liquid flow characteristics. Counting PPI is a standard way manufacturers and engineers classify foam porosity because it predicts permeability and surface area available for trapping particles or supporting media.

Important nuance: PPI is not a direct measure of pore volume or the minimum particle size captured; it is a structural count. Two different materials with identical PPI may show different flow resistance and capture efficiency because of cell-wall thickness, reticulation quality, and raw polymer chemistry.

10ppi 20 Ppi 30ppi Silicon Carbide Ceramic Foam Filter

2. Materials and manufacturing methods for reticulated filter foam

Most commercial 20 PPI filter foams are produced from reticulated polyurethane (PU) ether or polyester. The manufacturing process removes cell membranes in a foam block so the structure becomes an open skeletal network that allows fluid to pass freely while trapping solids on cell surfaces. Reticulation may be done thermally, chemically, or mechanically, and the quality of that reticulation heavily influences pressure drop and longevity.

Variants and coating options:

-

Base polymers: polyester vs ether PU — ethers tend to resist hydrolysis better, polyesters may offer different mechanical attributes.

-

Surface treatments: hydrophobic or hydrophilic coatings, silicone impregnation, or activated-carbon saturation for odour/adsorption tasks.

-

Reinforcement: stitched backing, adhesive layers, or composite laminates for structural support in high-flow or high-temperature settings.

For foundry and molten metal contexts, many operations instead use ceramic foam filters (alumina-based) rather than polymer foam; ceramic CFFs are rigid, chemically compatible with molten aluminum, and specified in PPI ranges such as 10–60 PPI depending on casting quality targets. When specifying “20 PPI” for metal filtration one must confirm whether polymer foam or ceramic foam is intended.

3. Typical physical and performance specifications (datasheet summary)

Below is a consolidated, typical specification set for commercial 20 PPI reticulated polyurethane filter foam drawn from common manufacturer datasheets (representative values). Use this table as a starting point and always verify with the supplier’s certificate of analysis for final design.

| Property | Typical value (example) | Test standard / notes |

|---|---|---|

| Cell count | 20 PPI ± 5 | visual / optical counting. |

| Apparent density | 1.3–1.6 PCF (approx.) | ASTM D3574 typical range. |

| Volumetric air flow (large sample) | ~20–25 CFM (sample dependent) | ASTM flow tests; varies with thickness and open area. |

| Tensile strength | ≥ 18 lb/in (typical) | datasheet minima, depends on polymer. |

| Elongation at break | ≥ 150–180% | ASTM D3574 common. |

| Temperature range (continuous) | -40 °C to ~90 °C (polyurethane) | limited vs ceramic media. |

| Chemical compatibility | Good with water and many oils; limited with strong oxidizers, hot acids | check supplier chemical guide. |

Key point: datasheet numbers vary between suppliers; the values above represent commonly seen ranges and should be validated for any critical process.

4. Why choose 20 PPI — performance tradeoffs and where it fits

20 PPI sits at a practical midpoint: it is coarser than fine foams (30–60 PPI) and finer than very coarse media (5–10 PPI). The tradeoff can be summarized:

-

Permeability: 20 PPI allows higher face velocity and lower initial pressure drop than higher-PPI media because the pore openings are larger. This keeps pumps and blowers from seeing excessive head loss in prefiltering stages.

-

Particle capture: It captures coarse-to-medium particulates effectively (e.g., sand, weld splatter, larger oxide films). For true sub-micron capture, 20 PPI is not sufficient by itself; a multi-stage filter with finer media downstream is required.

-

Clogging and maintenance: Coarser foams resist rapid surface sealing and therefore last longer between cleanings in many real-world systems. Forum and field reports often prefer 20–30 PPI for systems where clogging would otherwise create operational issues.

In molten aluminium filtration, engineers must choose between polymer foam (not used in contact with molten metal) and ceramic foam filters. A 20 PPI ceramic filter is commonly used for general casting where a balance of filtration efficiency and permeability is required. For high-integrity aerospace castings, higher PPI ceramics (30–60) may be specified.

5. Typical industrial and commercial applications

A. Foundry and aluminium casting

Alumina-based ceramic foam filters with 20 PPI are widely used in aluminium casting to reduce oxide inclusions and turbulence-induced defects while balancing melt flow. They are often placed in the gate or runner to smooth flow and trap slag. Choose ceramic CFFs if you will expose the filter to molten metal.

B. HVAC and air prefiltration

20 PPI reticulated foam works well as a reusable prefilter in HVAC units, removing coarse dust and debris without choking the system. Many off-the-shelf replacement foams are sold in 20 PPI for consumer and light-commercial filters.

C. Aquarium and pond filtration

Many aquarium filter cartridges and models use 20 PPI rated foam as the coarse layer in multistage cartridges; it captures larger particulates and protects biological media downstream. Manufacturer parts lists commonly denote 20 PPI for coarse replacement pads.

D. Liquid polishing and industrial process filtration

20 PPI foams serve as intake strainers, splash guards and gross-particle arrestors in chemical baths, cooling loop strainers and other industrial liquid systems.

6. Design and sizing recommendations

Designing a filtration stage with 20 PPI foam requires attention to face velocity (vf), thickness (t), and available surface area (A). The goal is to keep the pressure drop across the foam within acceptable limits while giving sufficient residence time and surface area for particle capture.

Quick sizing rules of thumb

-

Face velocity (air): Keep vf for disposable prefilters under 2.5–3.0 m/s for conservative performance; higher vf increases pressure drop and wear.

-

Face velocity (liquid): Depends on viscosity and particle load; start with 0.1–0.5 m/s for polishing stages and adjust by pilot tests.

-

Thickness: Typical foam thicknesses range from 6 mm to 50 mm. Thicker foam increases dust holding but raises initial pressure drop.

-

Redundancy: For higher dirt loads, use layers: coarse 20 PPI upstream, then 30–60 PPI or depth media downstream. This staging protects finer media and extends maintenance intervals.

Example calculation (air prefilter)

Given air flow Q = 1,000 m³/h and desired face velocity vf = 2 m/s, required area A = Q / vf = (1000/3600) / 2 ≈ 0.139 m². Select a panel of standard size with equal or larger free area to maintain the design velocity.

Always bench-test actual pressure drop vs flow with a production sample before finalizing fan and duct specifications. Manufacturer flow curves and ASTM-based testing are essential.

7. Installation, handling and maintenance best practices

-

Cutting and shaping: Use sharp blades and a straightedge. Bonding to frames is typically done with spray contact adhesives compatible with PU.

-

Orientation: Install foams so that the primary loading face receives the coarse feed to avoid pushing particulates into downstream stages.

-

Cleaning: For reusable foams, cleaning includes compressed-air back-blow (air systems), washing with low-pressure water or detergent (liquid systems), or gentle brushing. Avoid high-pressure washing that can tear the reticulated skeleton.

-

Replacement intervals: Dependent on loading; typical service ranges from weeks to months. See the replacement table below for common guidance.

-

Storage: Keep packaged in dry, ventilated storage away from direct sunlight and ozone sources; store flat to avoid permanent deformation.

8. Testing, quality control and acceptance criteria

To accept a production batch, request the supplier provide:

-

PPI count verification (visual sampling).

-

Density and tensile/elongation test reports (ASTM D3574 or equivalent).

-

Air or liquid flow vs pressure drop curves at standard thicknesses.

-

Chemical compatibility worksheet for the expected fluids and cleaning agents.

-

Certificate of origin and manufacturing date for traceability.

Common QC tests include cell-count, volumetric air flow, compression set and tear strength. Representative datasheets for 20 PPI foams list these parameters; request sample test coupons for in-house validation.

9. Common problems and troubleshooting

-

Rapid pressure rise: Usually caused by undersized surface area or unexpected particle loads. Remedy by upsizing area or adding a coarse prefilter.

-

Foam breakdown (crumbing): May result from chemical incompatibility or excessive temperature exposure. Switch to a more chemical-resistant polymer or change cleaning chemistry.

-

Channeling or bypass: Poor sealing at frames allows untreated fluid to bypass the foam. Use gasketing or adhesive retention frames.

-

Melt contamination in casting (ceramic case): If inclusions persist after adding a 20 PPI ceramic, consider a higher PPI ceramic or a two-stage ceramic arrangement (coarse + fine) and re-evaluate melt handling upstream.

10. Environmental, safety and compatibility notes

-

Polyurethane foam is combustible; when used in air systems comply with local fire codes and consider fire-retardant variants where required.

-

Disposal: Spent polymer foam is usually non-hazardous solid waste but check for adsorbed hazardous constituents (e.g., oils or heavy metals) before disposal.

-

Ceramic foams used for molten metal are brittle; handle with care. Spent ceramic filters may be considered industrial waste and often require separate handling.

11. Product selection checklist (quick procurement form)

| Item to confirm | Requirement / note |

|---|---|

| Intended medium | Air, water, oil, molten metal (ceramic) |

| Expected particle size distribution | Confirm D50 and largest particles |

| Flow rate and face velocity | Provide Q and design vf |

| Temperature exposure | Operating and cleaning temperatures |

| Chemical exposure | List chemicals the foam will contact |

| Thickness and panel size | Standard sizes or custom cuts |

| Certification needed | RoHS, REACH, UL (for flame retardance) |

| Replacement cadence | Estimate to size spare inventory |

| Supplier QC docs | PPI report, ASTM tests, COA |

12. Tables

Table A: Quick specification snapshot

| Parameter | Typical 20 PPI reticulated PU foam |

|---|---|

| Cell count | 20 ±5 PPI |

| Density | 1.3–1.6 PCF |

| Thickness options | 6 mm, 12 mm, 25 mm, 50 mm (custom) |

| Max continuous temp | ~80–100 °C (polyurethane) |

| Common color | Charcoal/black |

Table B. PPI vs common application (selection map)

| PPI | Typical use cases |

|---|---|

| 5–10 | Heavy debris straining, coarse liquid intake |

| 20 (this article) | General prefiltration, HVAC prefilter, aquarium coarse pad, foundry medium-grade ceramic filters (alumina CFF) for castings. |

| 30–60 | Fine polishing, biological media support, high-integrity castings (ceramic 30–60 PPI). |

Table C. Recommended replacement / service intervals (typical)

| Environment | Condition | Replace / clean |

|---|---|---|

| Aquarium, moderate bioload | weekly cleaning; replace every 6–12 months | Clean weekly, replace annually |

| HVAC prefilter, light dust | monthly visual checks | Replace 3–6 months |

| Industrial liquid with heavy solids | weekly or based on ΔP alarm | Clean weekly; replace when integrity lost |

| Casting ceramic filter | single-use (molten metal) | Replace after each pour |

20 PPI Reticulated Foam & Filtration FAQ

1. What particle sizes will a 20 PPI foam trap effectively?

2. Can I use polyurethane 20 PPI foam in contact with molten aluminum?

3. How often should 20 PPI foam be cleaned?

- Aquaria/Water: Weekly rinse.

- HVAC/Air: Monthly checks with 3-6 month replacement.

- Industrial Loops: Clean or replace when the differential pressure (Delta P) reaches your specific system design setpoint.

4. Does higher PPI always mean better filtration?

5. What are the typical mechanical properties of 20 PPI foam?

6. Can 20 PPI foam be cleaned and reused?

7. How is PPI (Pores Per Inch) actually measured?

8. What should I ask a supplier for when buying 20 PPI foam?

- PPI verification and tolerance.

- Density and pore size distribution.

- Flow velocity vs. Pressure Drop (Delta P) curves.

- Chemical compatibility report.

9. Are there fire-retardant 20 PPI foams available?

10. How does 20 PPI ceramic compare to 20 PPI polymer foam?

- Ceramic 20 PPI: Rigid, heat-stable (above 1000 degrees C), single-use for molten metals or industrial kilns.

- Polymer 20 PPI: Flexible, low-temperature (below 100 degrees C), washable, and suited for air/liquid pre-filtration.