Parameters for tundish nozzles

| Item | Standard size | Special size | Packing | Special packing |

| Tundish nozzle | 100-650mm | According to the drawing | 50 Pcs/Case | According to the drawing |

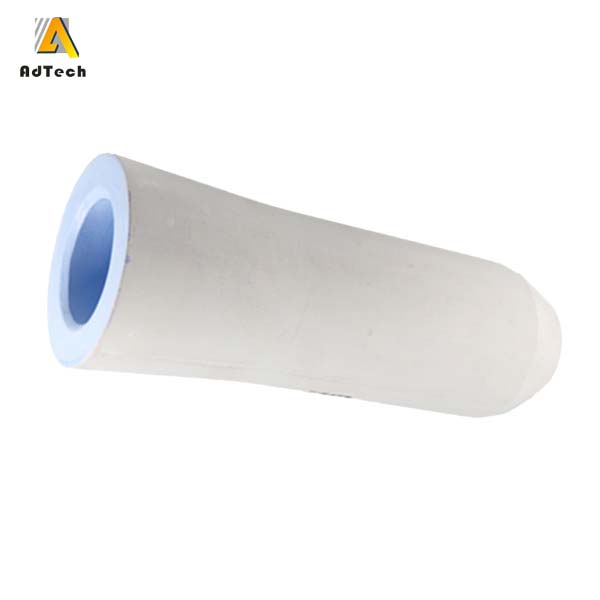

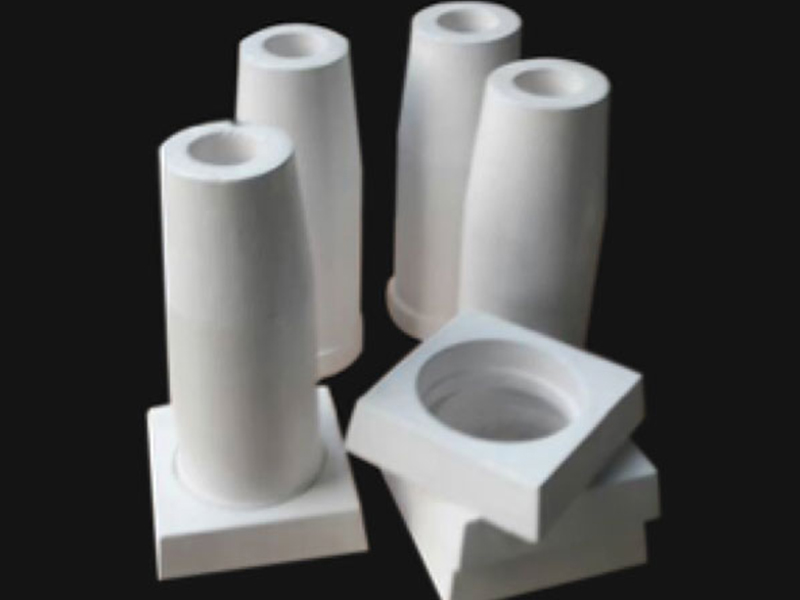

The tundish nozzle is also called ceramic tube, alumina tube, or casting tube. AdTech produces numerous kinds of outstanding Tundish Nozzles. AdTech tundish nozzles are appropriate for controlling the go with the flow of molten aluminum. It has a better overall performance compared to other nozzles. Tundish nozzles have advantages of heat preservation, reducing heat dissipation, reducing weight, increasing power, and improving carrier lifestyles. The collection of go-with-the-flow manipulates products consisting of alumina porcelain rods, ladle shrouds, refractory fiber cones, impurity separation earrings, and other merchandise. they may be used along with glide control to stabilize the steel casting parameters. The ceramic tube makes use of high-silicon molten material. It has sturdy corrosion resistance, no pollutants to the steel answer, and may be used a couple of times. The casting tube meets the technical wishes of producing high-cost-introduced, high-tech overall performance requirements for aluminum alloy precision casting products.

Tundish Nozzle advantages

High strength, erosion resistance, impact resistance, heat shock resistance, and smoother surface.

Extend the service life with the help of boron nitride (BN) paint.

Highly flexible in operation, and enhances the effect of molten metal transfer equipment.

Save energy and reduce consumption.

By controlling the flow of aluminum liquid, on the one hand, the uniformity of cast aluminum ingots can be improved, and the size of aluminum ingots can be more uniform. On the other hand, it can make the flow of molten aluminum in the diversion trough not increase and decrease suddenly and tend to a stable value. A protective oxide film is formed on the surface, which will not be destroyed. It evenly covers the surface of the molten aluminum, prevents the molten aluminum from oxidizing, reduces the loss of the molten aluminum, reduces the production cost of the enterprise, and improves the product quality.