Parameters of Adtech ceramic foam filters:

| Specifications(mm) | Effective filtration area(%) | Filtration flow range(kg/min |

| 7in(178*178*50) | 75 | 22-56 |

| 9in(229*229*50) | 75 | 25-80 |

| 12in(305*305*50) | 80 | 50-156 |

| 15in(381*381*50) | 85 | 85-252 |

| 17in(432*432*50) | 86 | 110-335 |

| 20in(508*508*50) | 88 | 160-478 |

| 23in(584*584*50) | 89 | 210-640 |

| 26in(660*660*50) | 90 | 276-830 |

Filtration rate for different PPI

| Pore Size (PPI) | 20 | 30 | 40 | 50 | 60 |

| PoreInclusions Diameter(um) | 80 | 40 | 20 | 10 | 5 |

| Filtration Rate(%) | 78 | 85 | 88 | 92 | 95 |

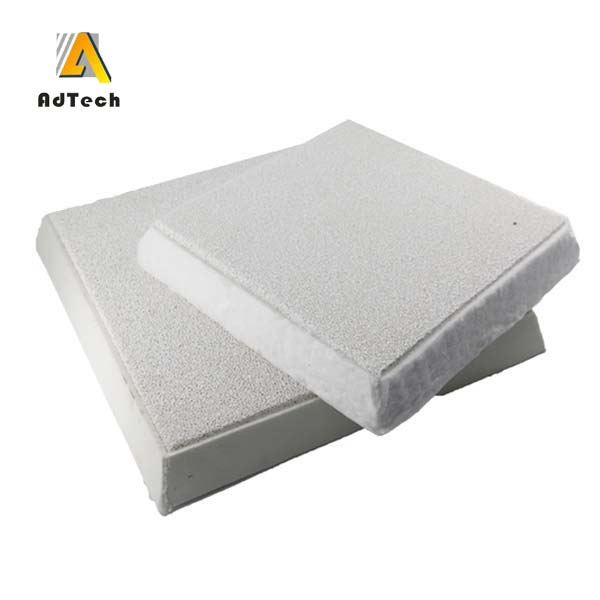

Ceramic foam filter overview

Adtech ceramic foam filters are used to purify aluminum liquid. They are usually used in the process of making aluminum sheets, ingots, coils, rods, and bars. They can also be used for producing aluminum cans or pans.

Why choose AdTech ceramic foam filters?

1. Adtech ceramic foam filters are more cost-effective than our competitors, with shorter supply times.

2. Our quality orientation makes us leaders of ceramic foam filter manufacturers in China.

3. We provide a one-stop service for all your aluminum liquid filtration needs.

4. We are service-oriented and quick to respond to any problems you may have.

5. We have a growing number of clients from more than 100 countries worldwide so far, such as EGA, Press Metal Bhd, Weiqiao, and Rusal.

6. Our Adtech ceramic foam filters have a higher filtration accuracy and passing rate. They are also friendly to the environment, as they are made without any carbon or graphite.

7. We also offer customized services for customers.

Ceramic foam filters application:

Adtech ceramic foam filters are used for filtrating and purifying aluminum liquid, in which they are placed into a filter box. So the size of the ceramic foam filter is determined by the size of the filter box.

Usually, they are usually used in the process of making aluminum sheets, ingots, coils, rods, and bars, also ceramic foam filters can be used for purifying aluminum liquid from waste, such as cans or pans.